Use it to plan your own robot barista payback period.

Want to know more details?

Please, contact your manager.

Aleksandr Maksimovich

Business Development Manager

Nalarobot Robotics | Nalarobot Café

Mobile: +375 333 760 460

(WhatsApp | Telegram | Viber)

BLOG

Revolutionizing Automation with Advanced Robot Motors for Enhanced Efficiency and Performance

The rapid advancement of technology has brought about a transformative impact on automation processes across various industries. According to a report by Fortune Business Insights, the global industrial robotics market is expected to reach $166.36 billion by 2024, growing at a compound annual growth rate (CAGR) of 26.7%. A significant contributor to this growth is the evolution of Robot Motors, which are vital components in enhancing the efficiency and performance of automated systems. These advanced motors not only improve precision and speed but also play a critical role in reducing energy consumption and operational costs, driving businesses towards greater productivity.

As industries seek to optimize their operations, the demand for high-performance Robot Motors continues to surge. Data from the International Federation of Robotics indicates that the number of operational industrial robots worldwide has surpassed 2.7 million units, highlighting the essential role that advanced motors play in this ecosystem. By revolutionizing automation with innovative Robot Motors, companies can unlock new possibilities for efficiency, enabling them to meet the increasing demands of the market while fostering sustainable practices. The future of automation hinges on these technological advancements, presenting a myriad of opportunities for industries willing to embrace change.

Driving Efficiency: How Advanced Robot Motors Transform Automation Landscapes

Smart manufacturing is fundamentally transforming automation landscapes, leveraging advanced technologies to enhance efficiency and performance. With the integration of advanced robot motors, manufacturers can achieve unprecedented levels of precision and speed in their operations. A recent report by the International Federation of Robotics indicates that the global demand for industrial robots is expected to grow by 10% annually, driven by innovations in motor efficiency and the expanding capabilities of robotic systems. As industries embrace digital transformation, the use of AI, IoT, and blockchain has become increasingly prevalent. These technologies enable real-time data analysis and decision-making, optimizing manufacturing processes and supply chains. A study from McKinsey highlights that companies implementing smart manufacturing technologies can see productivity increases of up to 30%, showcasing the considerable impact of advanced robot motors that power these new systems. Moreover, the surge in smart manufacturing practices is not only enhancing operational efficiencies but also driving workforce growth. The World Economic Forum projects that by 2025, automation will displace 85 million jobs while simultaneously creating 97 million new positions, emphasizing the critical role of advanced robot motors in facilitating this shift. These motors are essential for creating environments where human workers can focus on higher-value tasks, thus promoting sustainability in manufacturing by reducing waste and energy consumption.

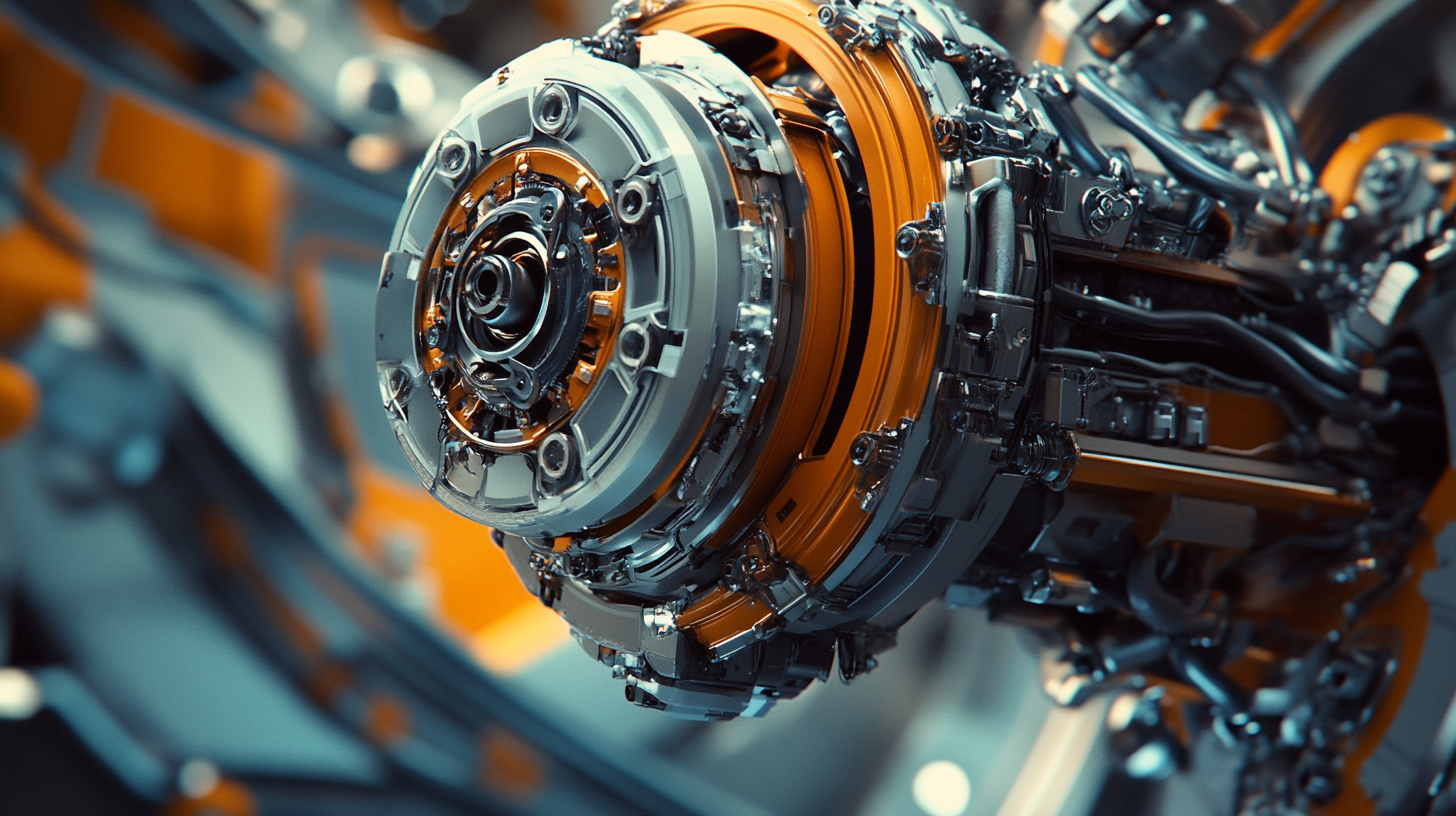

The Role of Torque and Speed in Enhancing Robotic Performance Metrics

The efficiency and performance of robotic systems are heavily influenced by the key parameters of torque and speed. In recent years, advancements in technology have paved the way for the development of high-performance robot motors that deliver impressive torque output while maintaining optimal speed. According to a report by MarketsandMarkets, the global industrial robotics market is projected to reach $75.8 billion by 2025, driven by the necessity for increased automation and efficiency across various sectors.

Torque, defined as the rotational force produced by the motor, is critical for applications requiring handling heavy loads, such as material handling and assembly tasks. Modern robot motors can achieve torque levels exceeding 10 Nm, significantly enhancing their capability to perform demanding tasks. For instance, collaborative robots (cobots) equipped with advanced motors not only boost productivity but also maintain safety standards, allowing them to work alongside humans seamlessly. A study by the International Federation of Robotics indicates that the use of such motors has resulted in productivity increases of up to 20% in manufacturing environments.

Speed is another crucial factor that complements torque in defining robotic performance. The right balance between speed and torque ensures that robots can complete tasks efficiently without compromising precision. The latest servo motors can achieve speeds of up to 6000 RPM, making them ideal for applications requiring quick cycles, such as pick-and-place operations. The combination of high torque at low speeds and the ability to reach high speeds enables robots to adapt to a wider range of applications, ultimately contributing to improved operational efficiency and reduced downtime across industries.

Industry Insights: Market Growth Projections for Robotic Motor Technologies

The Global Retail Robotics market is poised for significant growth, projected to reach a staggering USD 249.3 billion by 2033, with an impressive compound annual growth rate (CAGR) of 28.73%. This remarkable expansion can be attributed to the increasing demand for automation across various sectors, particularly in retail, where robotic technologies are revolutionizing operational efficiency and enhancing customer experiences.

Recent insights from industry reports highlight the key drivers behind this growth, including advancements in robotic motor technologies that enable faster and more precise automation solutions. As businesses seek innovative ways to streamline operations and reduce costs, the adoption of smart robotics powered by advanced motor systems is becoming essential. These motor technologies not only improve performance but also offer scalability for businesses looking to adapt to changing market dynamics.

Moreover, the demand for robotic applications is being fueled by the rise of e-commerce and the need for efficient supply chain management solutions. The integration of robotics into logistics and inventory management processes is creating opportunities for companies to optimize their workflows, ultimately leading to increased productivity and customer satisfaction. As we move forward, staying informed about emerging technologies and market trends will be crucial for stakeholders aiming to capitalize on the growing robotics market.

Comparative Analysis: Traditional Motors vs. Advanced Technologies in Robotics

The landscape of robotics is undergoing a significant transformation with the introduction of advanced robot motors that are setting new standards for efficiency and performance. To understand the impact of these innovations, it's essential to conduct a comparative analysis between traditional motors and modern technologies in the field of robotics.

Traditional motors, including brushed DC and stepper motors, have been the backbone of robotic applications for decades. While they are reliable and well-understood, these motors often fall short in terms of performance, energy efficiency, and adaptability. Their mechanical limitations can lead to increased wear and tear, resulting in shorter lifespans and higher maintenance costs. Additionally, traditional motors may struggle to meet the stringent demands of high-speed and high-precision tasks, which are increasingly common in advanced robotic systems.

In contrast, advanced robot motors, such as brushless DC motors and servo motors, leverage cutting-edge technology to deliver superior performance. These motors boast higher efficiency rates, reduced friction, and extended operational lifespans. They also offer fine-tuned control and responsiveness, allowing for more complex and dynamic movements. Enhanced features like real-time feedback and integrated sensors further improve a robot's performance, enabling it to adapt to its environment and tasks with unprecedented precision. As industries increasingly adopt innovative robotic solutions, the clear advantages of advanced motors over traditional counterparts become a critical factor in driving the future of automation.

Case Studies: Real-World Applications of Advanced Motors in Industrial Automation

In the rapidly evolving landscape of industrial automation, advanced robot motors are playing a pivotal role in enhancing efficiency and performance. Several case studies have emerged, showcasing real-world applications where these innovative motors have made significant contributions to operational success.

One notable example can be found in the automotive industry, where manufacturers have integrated high-precision servo motors into their assembly lines. These advanced motors not only improve speed and accuracy but also adapt seamlessly to varying production demands. A leading automotive manufacturer reported a 30% reduction in assembly time after implementing these servo motors, demonstrating how automation can achieve higher throughput while maintaining quality standards.

Another compelling case study comes from the food and beverage sector, where companies have adopted brushless DC motors in their packaging processes. These motors provide superior torque control and energy efficiency, allowing for faster and more reliable packaging operations. A global beverage brand witnessed a significant decrease in energy consumption—around 20%—by switching to advanced motors, which also minimized maintenance needs and downtime, resulting in cost savings and increased productivity.

These real-world applications highlight the transformative impact of advanced motors in automation. As industries continue to innovate, the integration of cutting-edge robot motors will undoubtedly pave the way for greater operational efficiencies and improved performance across various sectors.