The Ultimate Checklist for Choosing the Best Manufacturing Robots for Your Factory

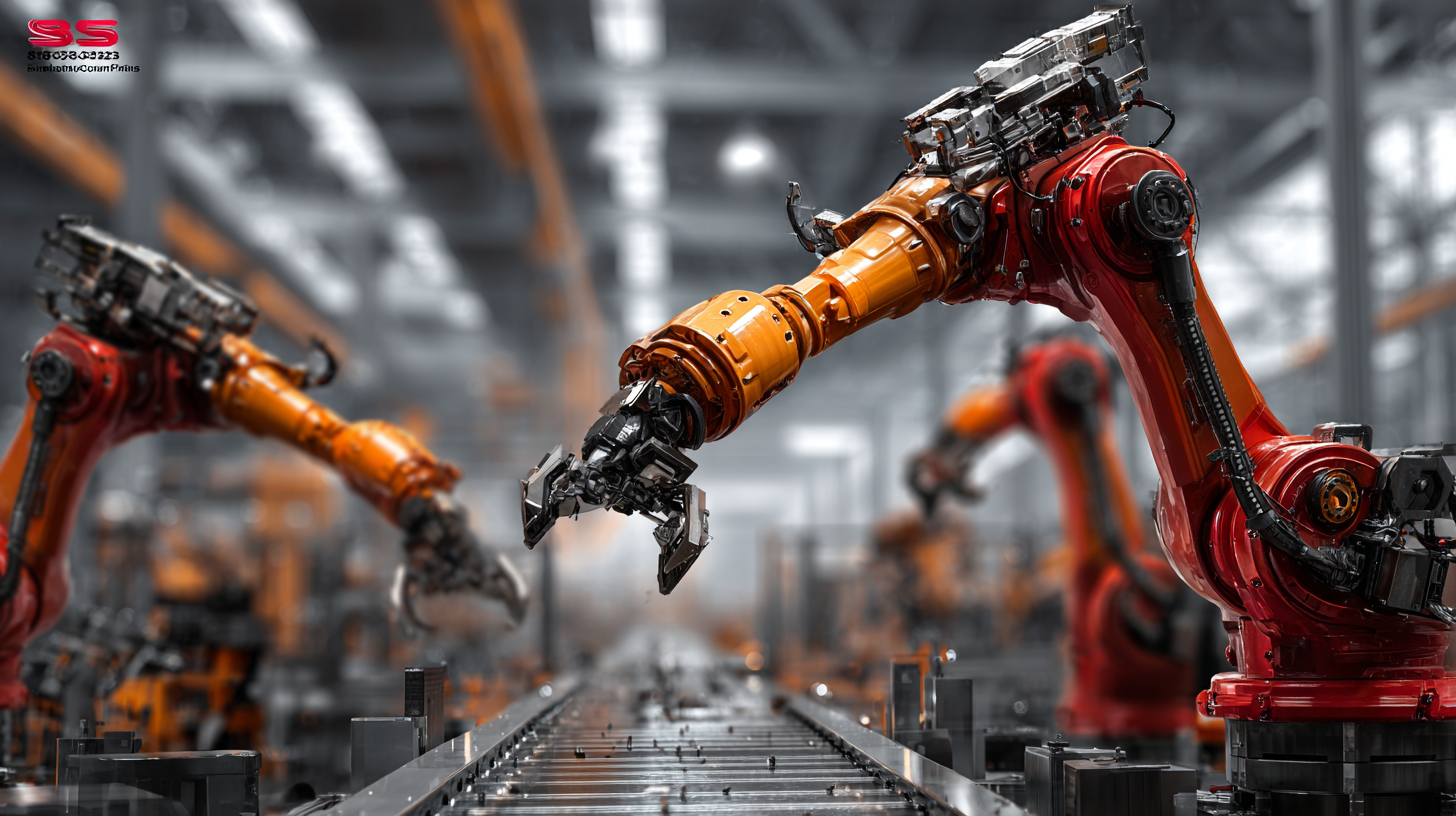

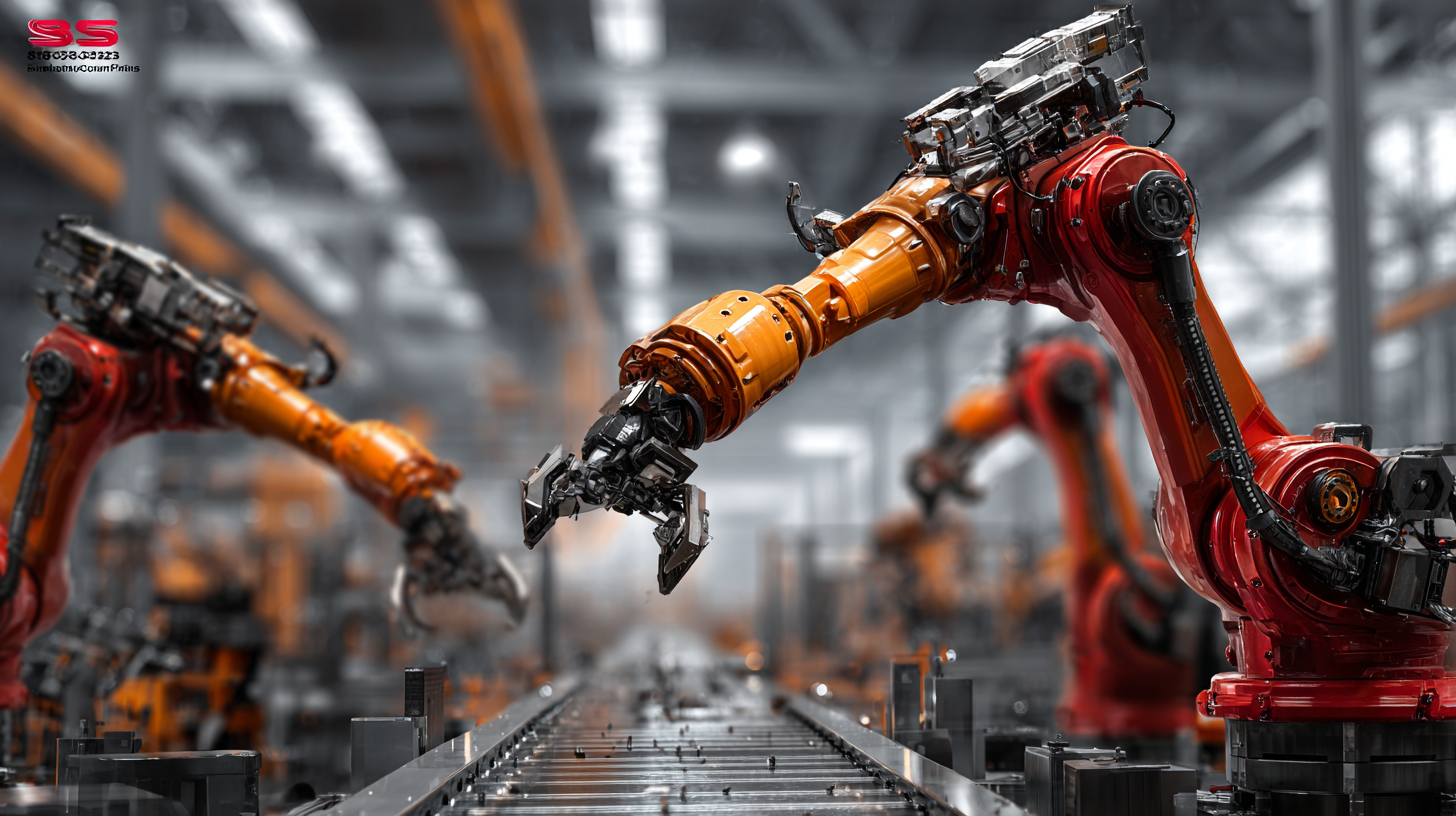

As the global manufacturing landscape evolves, the integration of

Manufacturing Robots has become a cornerstone of operational efficiency and productivity.

According to a report by the International Federation of Robotics, the number of

operational industrial robots has surged to over 3 million units worldwide, reflecting a growth trend of over

10% annually. This surge is driven by the increasing demand for high-quality production

and the necessity for manufacturers to remain competitive in an ever-changing market.

In China, the push for smart manufacturing has resulted in a

significant investment in robotics technology, making it a key player in the global supply chain. By harnessing the capabilities of

Manufacturing Robots, factories can not only improve their production capabilities but also ensure that they meet the stringent quality

standards that customers demand. In this blog, we present the ultimate checklist for selecting the best manufacturing robots tailored

to your factory's unique needs, ensuring you can leverage this transformative technology effectively.

Understanding the Importance of Import and Export Certifications in Manufacturing Robots

In the rapidly evolving landscape of manufacturing, navigating the import and export certifications for manufacturing robots is crucial for ensuring compliance and operational efficiency. According to the Ministry of Heavy Industries, the capital goods sector plays a pivotal role in bolstering India's manufacturing capabilities. This sector not only encompasses heavy engineering and machine tools but also promotes advancements in automation technologies, particularly in robotics. Manufacturers must ensure that their robots meet international certification standards to facilitate smoother entry into global markets, which is supported by the rising trend of "Make in India."

The demand for certified manufacturing robots is increasingly critical as companies look to enhance production quality while minimizing risks associated with non-compliance. Data from industry reports reveal that certified robots can lead to a 30% increase in operational efficiency, highlighting the significance of adhering to certification processes. Moreover, countries like the United States have stringent regulations regarding the importation of technological equipment; hence, manufacturers must prioritize obtaining the necessary certifications to avoid potential trade barriers. In this context, understanding the importance of import and export certifications will help factories leverage technological advancements, ultimately driving growth and sustainability in a competitive market.

Key Certifications to Look for When Sourcing Manufacturing Robots

When sourcing manufacturing robots for your factory, understanding the key certifications is crucial. The global market for Testing, Inspection, and Certification (TIC) is projected to expand significantly, increasing from $85.08 billion in 2022 to $281.17 billion by 2029. This surge showcases the heightened importance of compliance and quality assurance in industries adopting robotic technologies. Certifications not only ensure safety and performance standards but also help in streamlining integration processes and enhancing operational efficiency.

**Tip:** Always verify the certifications of robots you consider for your factory. Look for ISO certifications, which are benchmarks for quality and safety. Additionally, check for compliance with local regulations that can impact robot installation and use, ensuring the machinery meets industry-specific standards.

Moreover, the presence of humanoid robots in Europe highlights a trend where robots are becoming vital collaborators in sectors experiencing workforce shortages. These robots require robust certifications to prove their capability in real-world applications, ranging from industrial roles to customer-facing environments.

**Tip:** Consider the adaptability of the robot and its certifications for various applications. Robots with multi-functional abilities and certifications for various tasks can provide greater versatility and long-term value for your manufacturing processes.

The Ultimate Checklist for Choosing the Best Manufacturing Robots

Navigating Regulatory Requirements for International Robot Purchases

When considering international purchases of manufacturing robots, understanding regulatory requirements is crucial for compliance and operational success. A recent report from the International Federation of Robotics indicates that the global demand for industrial robots is projected to grow by 10% annually, which underscores the importance of navigating the complex regulatory landscape that can vary significantly by country. Regulations may include safety standards, certification processes, and import tariffs, all of which can influence the total cost and feasibility of robot integration in your factory.

Different countries adhere to varying regulatory frameworks; for instance, the European Union has stringent CE marking requirements to ensure that imported machinery meets health and safety standards. According to a study by McKinsey, companies that effectively comply with these regulations experience 20% faster time-to-market for their automation solutions. Engaging with local regulatory consultants can help manufacturers streamline this process, minimizing delays and ensuring that all necessary certifications are obtained before a robot is integrated into production lines. Staying informed about these regulations not only protects your investment but also enhances operational efficiency and competitiveness in the global market.

The Ultimate Checklist for Choosing the Best Manufacturing Robots for Your Factory

| Criteria |

Description |

Importance (1-5) |

Regulatory Compliance |

| Robot Type |

Select between industrial, collaborative, or specialized robots. |

5 |

ISO 10218 |

| Payload Capacity |

Ensure the robot can handle desired weight loads. |

4 |

CE Marking |

| Working Environment |

Assess indoor, outdoor, or hazardous location needs. |

3 |

UL Certification |

| Software Compatibility |

Check integration with existing systems and ease of programming. |

4 |

Open Standards Compliance |

| Safety Features |

Include emergency stops, sensors, and safety zones. |

5 |

ISO 12100 |

| Cost of Ownership |

Evaluate initial cost, maintenance, and operational costs. |

4 |

N/A |

| Supplier Reputation |

Research supplier history and customer feedback. |

3 |

ISO 9001 |

Impact of Certification on Robot Performance and Safety Standards

When selecting manufacturing robots for your factory, certification plays a critical role in ensuring both performance and safety standards. Certified robots are rigorously tested and validated against industry benchmarks, which can significantly reduce the risk of malfunctions and accidents. This testing process includes evaluating their operational capabilities, failure rates, and compliance with established safety protocols. Adopting robots with relevant certifications not only enhances reliability but also ensures adherence to the latest safety guidelines, ultimately leading to a safer work environment.

In addition to promoting safety, certified robots can offer significant advantages in efficiency and productivity. Many certification processes involve comprehensive assessments of a robot's operating speeds, precision, and energy consumption. A robot that meets these high standards is more likely to operate smoothly and consistently, reducing downtime and maintenance costs. Furthermore, having certified robots can also facilitate smoother integration into existing systems, enabling factories to optimize their workflows and boost overall performance. Investing in certified robots is not just a safety obligation; it’s a strategic decision that can elevate your factory’s operational effectiveness.

Strategies for Ensuring Compliance with Industry-Specific Certification Needs

When selecting manufacturing robots for your factory, it’s crucial to ensure compliance with industry-specific certification needs. Different sectors have varying regulations, and understanding these is essential for seamless operations. For example, if your factory handles sensitive data, you may need to incorporate data compliance regulations that cover security and governance. Familiarizing yourself with these regulations can prevent costly delays and penalties.

**Tips:** Always conduct thorough research on relevant certifications in your industry. Regularly update your knowledge about regulatory changes and implement appropriate training for your team to stay compliant. Additionally, consider integrating automated compliance solutions to streamline your processes.

Ensuring compliance isn’t just about following the rules; it can also drive business growth by building trust with clients and stakeholders. Making compliance an integral part of your manufacturing strategy can help you navigate the complex landscape of industry regulations.

**Tips:** Engage with compliance experts or consultants who can provide insights specific to your industry. Developing a robust compliance program that is flexible enough to adapt to changing regulations will minimize risks and enhance operational efficiency.