Overcoming Challenges with Best Cnc Robot Arm Solutions for Global Buyers

As we look ahead to 2025, the landscape for CNC robot arms is poised for significant transformation, driven by rapid advancements in automation and the increasing demand for precision in manufacturing processes. According to a recent market analysis by Industry Research, the global CNC robot arm market is expected to reach $XX billion by 2025, growing at a CAGR of XX% from 2020 to 2025. This surge is attributed to the escalating need for efficiency and productivity in various sectors, particularly in automotive, electronics, and consumer goods. With challenges such as labor shortages and rising production costs, global buyers are seeking the best CNC robot arm solutions to enhance operational capabilities. In this blog, we will delve into the current challenges faced by manufacturers and explore innovative solutions that are shaping the future of CNC robotics, ensuring businesses remain competitive in an evolving market.

Exploring the Rising Demand for CNC Robot Arms in Global Markets

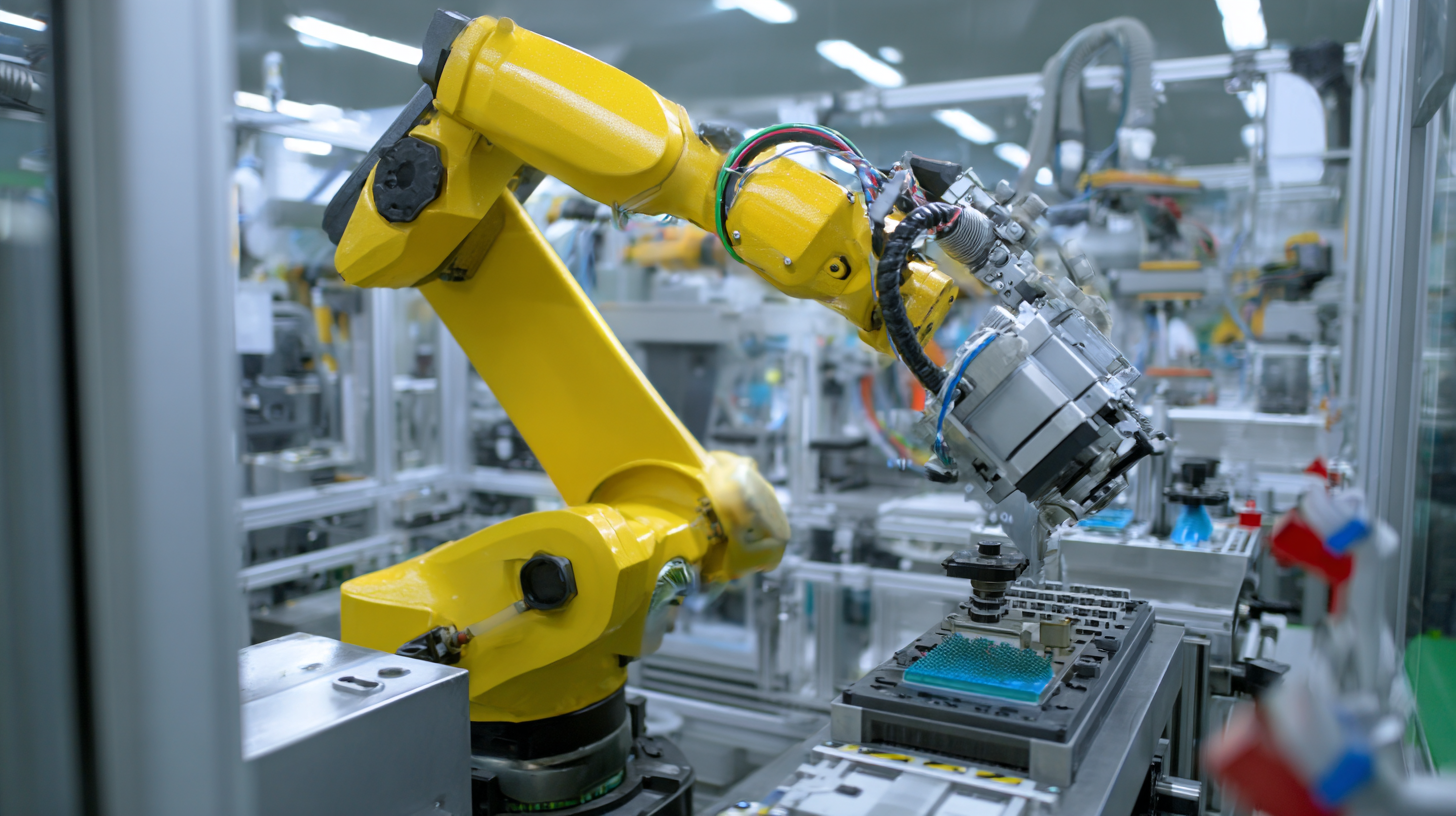

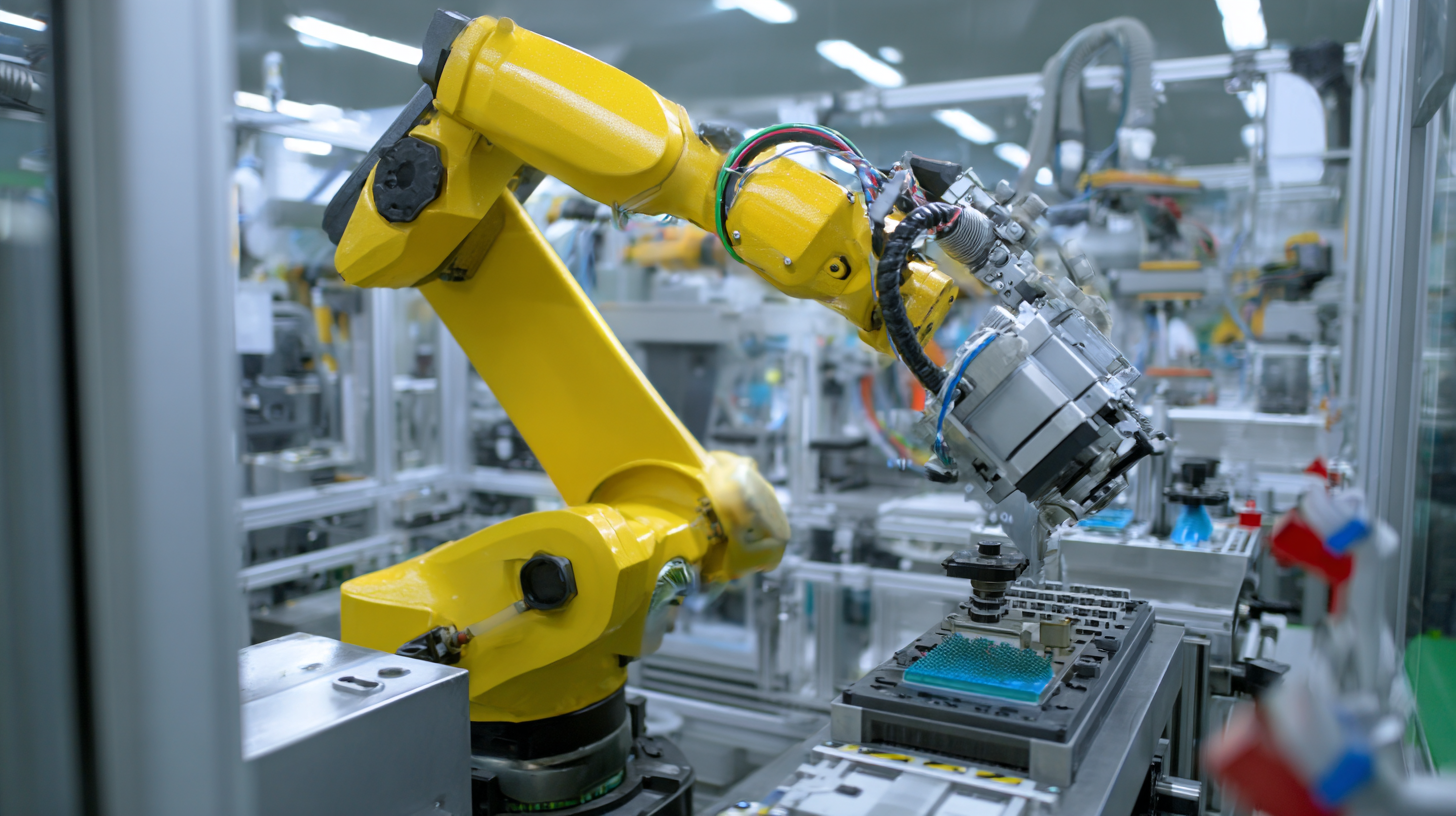

The demand for CNC robot arms is surging across global markets, driven by the increasing need for precision, efficiency, and flexibility in manufacturing. As industries continue to embrace automation, CNC robot arms have emerged as essential tools for tasks ranging from intricate assembly to precise machining. This rising trend is particularly evident in sectors such as automotive, aerospace, and electronics, where the ability to enhance production capabilities and minimize human error is paramount.

Furthermore, global buyers are seeking best-in-class solutions that offer not only advanced technology but also adaptability to diverse manufacturing processes. Manufacturers are responding by developing innovative CNC robot arms that integrate cutting-edge features such as machine learning and artificial intelligence. This transformation allows businesses to enhance operational throughput and ensure quality control while addressing specific needs unique to each market segment. As competition intensifies, the focus on sourcing the best CNC robot arm solutions is crucial for those looking to maintain a competitive edge in this rapidly evolving landscape.

Key Features and Advantages of Advanced CNC Robot Arm Solutions

In the fast-evolving landscape of Industry 4.0, advanced CNC robot arm solutions have become indispensable for global buyers seeking to enhance operational efficiency and precision. These solutions are designed with key features that address the unique challenges faced by various industries, from manufacturing to textiles. For instance, collaborative robots enable seamless task allocation among multiple units, ensuring optimal production scheduling and streamlined workflows. This not only minimizes downtime but also boosts productivity by allowing machines to adapt to changing demands in real-time.

Moreover, the integration of smart robotics into sectors like garment manufacturing is revolutionizing traditional processes, including cutting and sewing. The automation of these tasks leads to increased accuracy and reduced labor costs, effectively tackling the issues of inconsistency and safety hazards associated with manual labor. By leveraging advanced CNC robot arm technology, businesses can transform their production lines into highly efficient systems that are responsive to market needs, cementing their competitive edge in a global marketplace.

Addressing Common Challenges in CNC Robotics Integration

Integrating CNC robotics in manufacturing processes presents several challenges that global buyers must navigate. One of the primary issues is the complexity of integrating new technology with existing systems. Many manufacturers are reluctant to overhaul their entire setup, fearing production delays and increased downtime. The key to overcoming this hurdle lies in selecting the right CNC robotic arm solutions that offer seamless compatibility with a variety of machinery and workflows. By opting for modular systems or those that are designed with flexibility in mind, businesses can enhance their automation capabilities without compromising their operational efficiency.

Another common challenge is the training and skill gap among employees. As CNC robotics become more prevalent, the need for skilled personnel who can operate and maintain these advanced systems increases. To tackle this issue, companies can invest in comprehensive training programs that not only familiarize workers with the new technology but also emphasize the importance of continuous learning in the fast-evolving manufacturing landscape. Solutions like simulation training and digital twins can provide invaluable practice without the high costs associated with real-world setup. Addressing these challenges effectively is crucial for manufacturers aiming to leverage the benefits of CNC robotics for improved productivity and competitiveness.

Future Trends: Innovations Shaping the CNC Robot Arm Industry by 2025

The CNC robot arm industry is on the brink of transformation, driven by innovations that aim to enhance efficiency and precision by 2025. With advances in AI and machine learning, robot arms are becoming smarter, capable of making real-time decisions and adapting to varying tasks without extensive programming. As these technologies mature, we can expect to see a rise in collaborative robots, or cobots, that work alongside humans, increasing productivity while ensuring safety on the shop floor.

Tips for buyers looking to invest in CNC robot arms include focusing on interoperability. As systems evolve, it's crucial to choose machines that can easily integrate with existing manufacturing setups. Additionally, investing in training for operators will maximize the benefits of these advanced technologies. Understanding the capabilities of new automation tools can significantly improve workflow efficiency and resource management.

Another trend shaping the future of CNC robot arms is the increasing emphasis on sustainability. Manufacturers are striving to create energy-efficient models that minimize waste and reduce carbon footprints. Buyers are encouraged to look for solutions that offer innovative energy-saving features, as well as those that promote sustainable practices throughout the production cycle. Keeping an eye on these trends will ensure that investments remain relevant and beneficial in the rapidly evolving industrial landscape.

Overcoming Challenges with Best Cnc Robot Arm Solutions for Global Buyers - Future Trends: Innovations Shaping the CNC Robot Arm Industry by 2025

| Feature |

Current Trends (2023) |

Predicted Trends (2025) |

Challenges |

Solutions |

| Precision and Accuracy |

High precision with improved control systems |

Enhanced algorithms for greater accuracy |

Manufacturing process variability |

Implementation of AI-based predictive maintenance |

| Cost-Effectiveness |

Growing adoption in small to medium enterprises |

Lower production costs through automation |

High initial investment |

Flexible financing options and leasing |

| Integration with Industry 4.0 |

Increased connectivity and data utilization |

Full automation and smart manufacturing |

Complexity of systems integration |

User-friendly software and training |

| Safety and Compliance |

Enhanced safety protocols in operation |

Advanced safety features with AI monitoring |

Adherence to changing regulations |

Regular audits and compliance training |

| Flexibility and Versatility |

Use in various applications from automotive to electronics |

Customizable options for diverse industries |

Limitations in current designs for niche uses |

Modular designs for quick adaptation |

Strategic Considerations for Importing CNC Robot Arms Worldwide

In recent years, the global market for CNC robot arms has experienced significant growth, driven by advancements in automation and manufacturing efficiency. According to a report by MarketsandMarkets, the CNC machine market is expected to reach $117 billion by 2026, growing at a CAGR of 7.5%. This surge presents a strategic opportunity for global buyers looking to import CNC robot arms and enhance their production capabilities.

When considering the importation of CNC robot arms, it is crucial to evaluate key factors such as supplier reliability, cost-effectiveness, and compliance with international standards. Buyers should conduct thorough research on potential suppliers and examine their certifications, production capacity, and reputation within the industry. Additionally, understanding the nuances of import regulations and tariffs can lead to more informed purchasing decisions. A 2023 report by ResearchAndMarkets highlights that effective supply chain management can reduce operational costs by up to 20%, making strategic planning essential for success in this competitive landscape.