Use it to plan your own robot barista payback period.

Want to know more details?

Please, contact your manager.

Aleksandr Maksimovich

Business Development Manager

Nalarobot Robotics | Nalarobot Café

Mobile: +375 333 760 460

(WhatsApp | Telegram | Viber)

BLOG

Unlocking Efficiency in Automation with Small Robotic Arms for Your Business

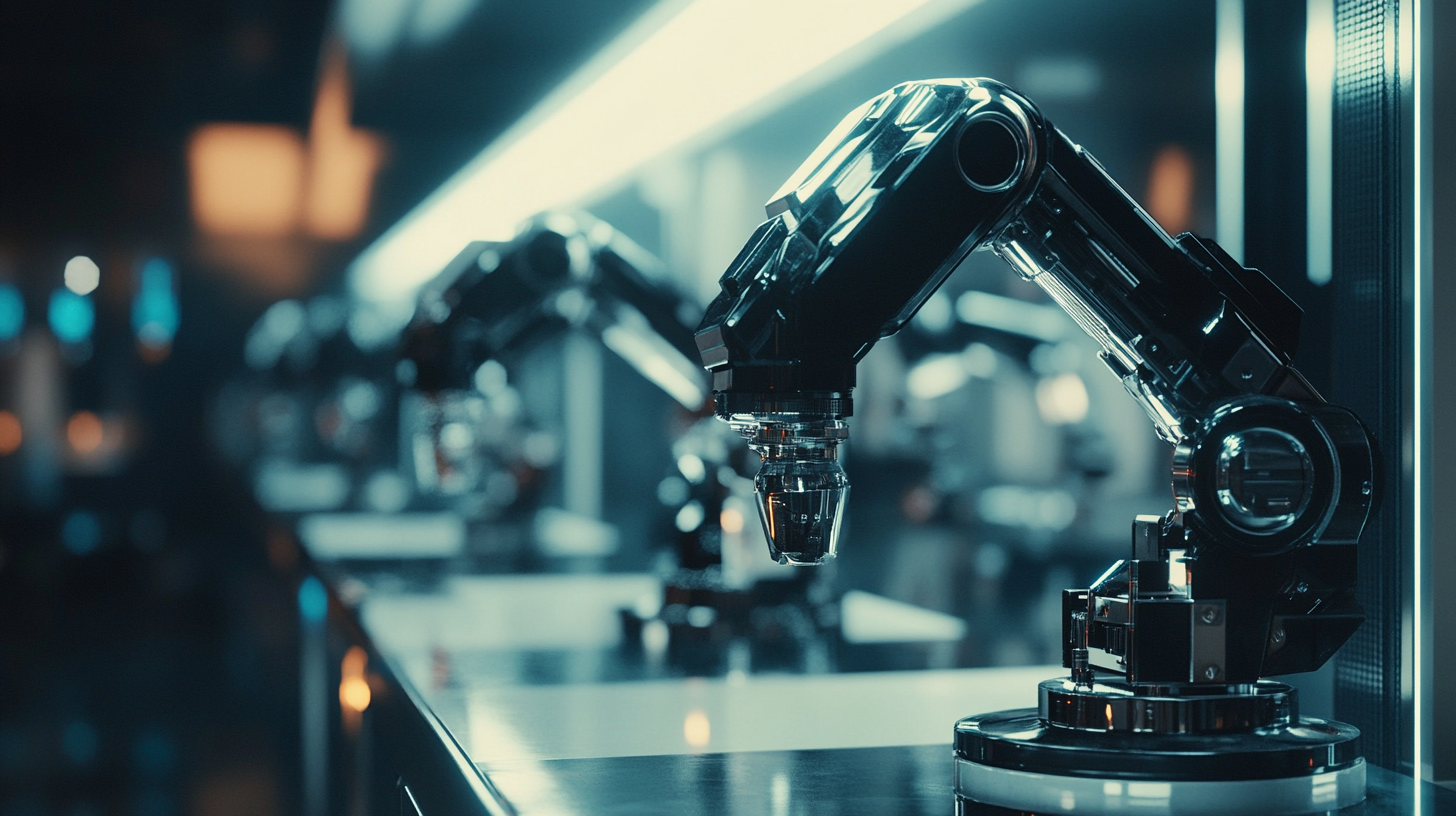

In recent years, the adoption of automation technologies has skyrocketed, revolutionizing operations across various industries. According to a report by McKinsey & Company, automating just 50% of current tasks could lead to productivity increases of up to 30% in manufacturing settings. One particular innovation driving this transformation is the use of Small Robotic Arms. These agile, compact robots are designed to perform precise tasks in confined spaces, making them ideal for small to medium-sized enterprises seeking to enhance efficiency without overwhelming their production lines.

As businesses face the growing need to maximize output while minimizing costs, the introduction of Small Robotic Arms presents a compelling solution. A study by the International Federation of Robotics revealed that the global market for industrial robots is expected to reach $70 billion by 2025, with a significant portion attributed to smaller robotic systems. By embracing these efficient tools, companies can not only streamline their operations but also stay competitive in a rapidly evolving marketplace, showcasing the critical role that Small Robotic Arms will play in the future of automation.

Benefits of Small Robotic Arms in Streamlining Business Operations

In today's fast-paced business environment, small robotic arms are emerging as a game changer for companies looking to enhance operational efficiency. These compact machines offer an array of benefits that streamline various processes, ultimately allowing businesses to focus on growth and innovation. One of the most significant advantages is their ability to perform repetitive tasks with high precision and reliability, reducing the occurrence of human error. This not only saves time but also minimizes waste, allowing companies to allocate resources more effectively. Moreover, small robotic arms can be easily integrated into existing workflows, enhancing flexibility and adaptability. Whether in assembly lines, packaging, or even quality control, these robots can be programmed to handle multiple tasks with minimal downtime. This adaptability is crucial in industries where production demands can fluctuate, enabling businesses to respond quickly to market changes without the need for extensive retraining of the workforce. Additionally, the use of small robotic arms can lead to substantial cost savings. By automating routine tasks, companies can reduce labor costs and reassign human workers to more strategic roles that require creativity and problem-solving skills. This shift not only improves employee satisfaction but also boosts overall productivity as teams tackle more complex projects. The implementation of small robotic arms represents a significant step toward achieving a more efficient, cost-effective future in business operations.

Key Industries Adopting Small Robotic Arms for Enhanced Productivity

Small robotic arms are transforming the landscape of various industries by enhancing productivity and streamlining operations. Manufacturing, for instance, has been one of the early adopters of these innovative devices. With their precision and flexibility, small robotic arms effectively handle repetitive tasks, freeing up human workers for more complex and strategic roles. This shift not only boosts efficiency but also reduces the likelihood of errors, resulting in higher quality output.

In the realm of e-commerce and logistics, small robotic arms are revolutionizing how goods are sorted, packed, and shipped. Their ability to operate in tight spaces allows businesses to maximize their warehouse operations. With the demand for faster delivery times, these robots can quickly adapt to various packaging requirements, ensuring that products reach customers more efficiently. This agility in handling tasks is vital as businesses strive to meet the rising expectations of consumers in a fast-paced market.

Moreover, the healthcare sector is witnessing a surge in the use of small robotic arms to assist in surgeries and rehabilitation processes. These robots provide surgeons with enhanced precision and control, leading to less invasive procedures and quicker recoveries for patients. In rehabilitation, small robotic systems help patients regain mobility more effectively, showcasing the versatility of technology in improving quality of life while simultaneously increasing operational efficiency within healthcare facilities.

Cost-Benefit Analysis: Investing in Small Robotic Arms for Your Business

Investing in small robotic arms offers businesses a substantial opportunity for cost savings and efficiency enhancements. According to recent forecasts, the collaborative robot market is set to reach an impressive $6.97 billion by 2033, driven by increasing demand across various industries. These small-scale robots are particularly advantageous for businesses looking to optimize production lines, reduce downtime, and mitigate labor costs. They not only improve speed but also enhance precision in tasks, making them indispensable in sectors like manufacturing and logistics.

The integration of robotic arms can lead to significant cost benefits, especially for companies investing heavily in automation. Firms that allocate at least 20% of their IT budget towards automation have reported remarkable reductions in process costs. Furthermore, as industries move towards automated solutions, the potential for small robotic arms to pay for themselves is becoming increasingly clear. For instance, in aerospace and defense manufacturing, companies evaluating the cost versus savings of these systems are finding that the initial investment quickly translates into long-term savings.

With the rapid advancements in robotics, especially in the context of e-commerce and logistics, companies are now utilizing small robotic arms not just for assembly but also for enhancing inventory management and packing efficiency. These innovations are reshaping traditional business models, allowing organizations to respond swiftly to market demands while maintaining optimal operational costs. As the robotics landscape evolves, adopting small robotic arms will not only be a strategic investment but also a catalyst for ongoing improvement in business efficiencies.

Case Studies: Successful Implementations of Small Robotic Arms

In the ever-evolving landscape of automation, small robotic arms have emerged as a pivotal solution for businesses seeking enhanced efficiency. Notably, the use of these robots is finding traction in various sectors, as exhibited by BMW Group's Spartanburg plant—the first production facility worldwide to successfully implement direct human-robot cooperation in series production. This groundbreaking application not only showcases the capabilities of small robotic arms but also highlights the significant potential for improved productivity and safety in complex manufacturing environments.

Case studies from industry giants like Bank of America and Amazon further illustrate the efficacy of robotic arms in streamlining operations. In the banking sector, for example, robotic automation has transformed routine tasks, allowing employees to focus on more strategic initiatives. Similarly, in warehousing, Amazon leverages small robots to enhance sorting and packing processes, reducing delivery times and operational costs. These implementations reflect a broader trend towards 'cobotics', where collaborative robots work alongside humans to achieve unprecedented levels of efficiency, a hallmark of Industry 5.0.

Furthermore, the evolving roles of collaborative robots are revolutionizing workplace dynamics by fostering an inclusive environment that thrives on innovation. As organizations like NASA and Evergreen demonstrate through their robotics applications, the integration of AI and small robotic arms not only maximizes productivity but also enhances decision-making processes. The ongoing research and successful implementations across industries underscore the transformative impact that these small robotic arms can have on modern business operations, paving the way for a future where human-robot collaboration is seamlessly integrated into everyday workflows.

Future Trends: Innovations in Small Robotic Arm Technology and Their Impact

The landscape of automation is rapidly evolving, and small robotic arms are at the forefront of this transformation. These devices, once considered niche tools, are now becoming integral to various industries, ranging from manufacturing to healthcare. Innovations in small robotic arm technology are leading to greater efficiency, precision, and flexibility in operations. With advancements in AI and machine learning, these robots can adapt to new tasks and environments, significantly reducing downtime and improving productivity.

Future trends point towards enhanced collaboration between humans and robots. Newer models are designed with safety features and intuitive interfaces, making them suitable for a wider range of applications. For instance, machine vision systems integrated into robotic arms allow for improved accuracy in tasks such as assembly and quality control. Additionally, the development of lighter, more agile robotic arms enables them to operate alongside human workers, facilitating a seamless integration into existing workflows.

Moreover, as the Internet of Things (IoT) continues to expand, small robotic arms are becoming increasingly interconnected. This connectivity allows for real-time data sharing and analysis, paving the way for smarter manufacturing processes. The ability to monitor and adjust operations based on live feedback can lead to significant cost savings and more efficient resource utilization. As these innovations unfold, businesses that adopt small robotic arms will find themselves at a competitive advantage in an ever-changing marketplace.