7 High-Performance Features of the Desktop Robot Arm That Will Transform Your Workflow

In an era where efficiency and automation are paramount,

the emergence of the Desktop Robot Arm is set to revolutionize various industries.

According to a report by MarketsandMarkets, the global robotics market is projected to reach

$210 billion by 2025, driven largely by advancements in

automation technologies. These compact and versatile robotic arms offer a range of high-performance features that can

significantly enhance workflows across sectors from manufacturing to

research and design.

With their ability to perform repetitive tasks with precision, integrate seamlessly with existing systems, and

reduce operational costs, Desktop Robot Arms are not just a trend but a transformative tool for businesses aiming to innovate and stay competitive.

As we delve into the seven high-performance features of the Desktop Robot Arm, it becomes clear that the future of

automation is both accessible and impactful.

In an era where efficiency and automation are paramount,

the emergence of the Desktop Robot Arm is set to revolutionize various industries.

According to a report by MarketsandMarkets, the global robotics market is projected to reach

$210 billion by 2025, driven largely by advancements in

automation technologies. These compact and versatile robotic arms offer a range of high-performance features that can

significantly enhance workflows across sectors from manufacturing to

research and design.

With their ability to perform repetitive tasks with precision, integrate seamlessly with existing systems, and

reduce operational costs, Desktop Robot Arms are not just a trend but a transformative tool for businesses aiming to innovate and stay competitive.

As we delve into the seven high-performance features of the Desktop Robot Arm, it becomes clear that the future of

automation is both accessible and impactful.

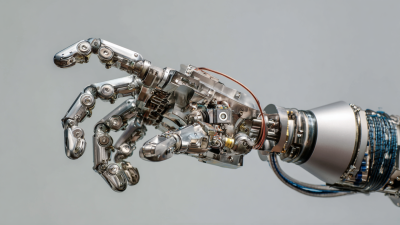

Innovative Design Elements That Maximize Precision and Efficiency in Desktop Robot Arms

The modern workspace is increasingly integrating advanced technology, among which the desktop robot arm stands out with its innovative design elements that enhance precision and efficiency. Recent industry reports indicate that the use of robotic arms in desktop applications has seen a growth rate of approximately 15% year-over-year, a clear testament to their rising importance. By utilizing enhanced sensors and AI-driven algorithms, these robotic arms can perform intricate tasks with a precision of up to 0.1 mm, significantly reducing human error and streamlining workflows.

For optimal results, consider integrating the robot arm with software that allows for real-time adjustments and telemetry. This ensures that any shift in workload or requirements can be addressed immediately, maximizing efficiency. Furthermore, regular calibration of the device can enhance accuracy, allowing businesses to maintain high standards and consistency in production.

Another recommended practice is to utilize modular attachments to expand the functionality of your desktop robot arm. According to recent data, companies that adapt their robotic systems for various tasks can see productivity increases of up to 30%. Such versatility not only optimizes operations but also enables teams to focus on more strategic activities, uplifting the overall workflow.

Advanced Motion Control Technologies for Enhanced Workflow Integration

In today's fast-paced work environment, advanced motion control technologies in desktop robot arms are revolutionizing workflow integration. According to a recent report by the International Federation of Robotics, the adoption of robotic systems has increased by over 15% annually, highlighting their growing significance in enhancing productivity across various industries. These arms, equipped with precision motion control, enable tasks ranging from assembly to quality inspection with remarkable accuracy, ultimately streamlining operations.

In today's fast-paced work environment, advanced motion control technologies in desktop robot arms are revolutionizing workflow integration. According to a recent report by the International Federation of Robotics, the adoption of robotic systems has increased by over 15% annually, highlighting their growing significance in enhancing productivity across various industries. These arms, equipped with precision motion control, enable tasks ranging from assembly to quality inspection with remarkable accuracy, ultimately streamlining operations.

Implementing a desktop robot arm can significantly reduce cycle times. For instance, automation of repetitive tasks allows human workers to focus on more complex projects, leading to a more efficient workload distribution. A study by McKinsey & Company revealed that up to 30% of tasks in various sectors can be automated, which directly translates to improvements in productivity and reduced operational costs.

Tips: When considering upgrading to a desktop robot arm, assess your specific workflow needs. Integrate the robot arm with existing software systems for seamless operation. Also, invest in training sessions for your team; effective utilization of this technology can yield impressive ROI and enhance overall performance. Adopting these technologies not only modernizes your workspace but also positions your business at the forefront of innovation.

Customization Options That Simplify Complex Tasks and Boost Productivity

In today's fast-paced work environments,

productivity hinges on the ability to streamline complex tasks.

Desktop robot arms offer robust customization options that empower users to tailor operations specifically to their workflow needs.

According to a report by McKinsey, automation could increase productivity rates by up to 1.4% annually,

highlighting the critical role of customizable technology in enhancing efficiency. By adjusting the robot arm to accommodate unique tasks—whether

assembling, sorting, or packaging—businesses can eliminate bottlenecks and ensure precision in every operation.

Furthermore, a study from the International Federation of Robotics reveals that integrating flexible automation solutions like desktop robot arms can

reduce operational costs by as much as 30%. This significant cut allows companies to

reallocate resources towards innovation and growth. The versatility of these desktop systems not only reduces the learning curve for employees

but also enables the reconfiguration of workflows in response to changing demands, making it easier than ever to maintain productivity in

dynamic environments. By leveraging these high-performance features, businesses are positioned to thrive and adapt

in an increasingly automated world.

User-Friendly Interfaces for Streamlined Operation and Management

The user-friendly interfaces of desktop robot arms are a game changer for professionals seeking to enhance their workflow. By integrating intuitive controls, these robotic systems allow users to operate complex tasks with minimal training. This streamlined operation not only boosts productivity but also reduces the likelihood of errors, making it easier for individuals to focus on their core responsibilities rather than grappling with intricate machinery.

In tandem with powerful performance features, the emphasis on user experience in desktop robot arms reflects a broader trend seen across various software solutions in 2025. Just as leading retail POS and CRM software prioritize ease of use to help businesses manage customer interactions, scheduling, and inventory efficiently, desktop robot arms offer a similar promise for automation in the workspace. The combination of advanced functionality and user-friendly design encourages seamless integration into existing workflows, leading to a transformative impact on task management and efficiency in any operational setting.

7 High-Performance Features of the Desktop Robot Arm That Will Transform Your Workflow

| Feature |

Description |

Benefits |

User-Friendliness Rating (1-5) |

| Precision Control |

Highly accurate movement capabilities for detailed tasks. |

Improves the quality of work and reduces errors. |

5 |

| Modular Design |

Interchangeable parts for customization. |

Allows for tailored solutions to specific tasks. |

4 |

| Intuitive Software Interface |

User-friendly control software with easy navigation. |

Reduces the learning curve for new users. |

5 |

| Real-Time Monitoring |

Live feedback on operation status and performance. |

Enhances productivity by allowing quick adjustments. |

4 |

| Safety Features |

Built-in sensors and emergency stop functionalities. |

Ensures safe operation and minimizes workplace accidents. |

5 |

| Versatile Applications |

Can perform various tasks across different industries. |

Offers flexibility for adaptation to changing needs. |

5 |

| Affordable Integration |

Cost-effective solutions for automation in small businesses. |

Makes automation accessible for companies with limited budgets. |

4 |

Real-World Applications of Desktop Robot Arms Driving Industry Transformation

Desktop robot arms are revolutionizing various industries by enhancing productivity and precision in multiple real-world applications. According to a report by the International Federation of Robotics, the global market for industrial robots is expected to reach over $60 billion by 2025, with desktop automation playing a significant role in this growth. Businesses integrating these innovative solutions into their workflows are witnessing drastic improvements in efficiency, often reducing production times by up to 30%.

In sectors like electronics, automotive, and medical manufacturing, desktop robot arms are increasingly adopted for tasks such as assembly, soldering, and 3D printing. A study from McKinsey & Company revealed that nearly 70% of businesses have accelerated their automation strategies in response to the pandemic, highlighting the growing reliance on robotic technology. Additionally, a survey by Deloitte indicated that 73% of executives believe that automation will be a critical success factor in driving enterprise performance, emphasizing the transformative power of desktop robot arms in today’s competitive landscape. As these technologies continue to evolve, their impact on workflow optimization and operational efficiency is undeniable.

In an era where

In an era where  In today's fast-paced work environment,

In today's fast-paced work environment,