2026 How to Choose Electric Ball Valves for Your System?

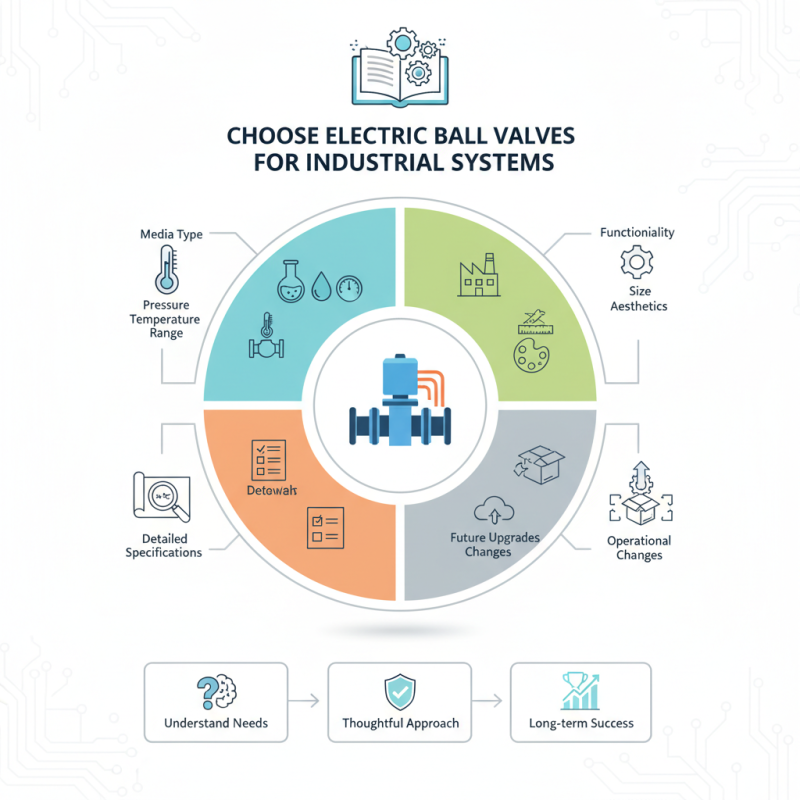

When it comes to controlling fluid flow in industrial systems, Electric Ball Valves play a crucial role. These valves offer a seamless and reliable way to manage various applications. Choosing the right Electric Ball Valves is essential for efficiency and safety.

Different factors can impact your selection. For example, the type of media, pressure requirements, and temperature range are critical. A mismatch can lead to performance issues. It's not just about functionality; aesthetics and size also matter. Making the wrong choice can result in operational challenges.

Understanding your system's specific needs is vital. Gather detailed specifications before making a decision. Don't overlook the potential need for future upgrades. Reflect on the possible changes in your operations. A thoughtful approach can lead to long-term success with your Electric Ball Valves.

Understanding Electric Ball Valves: Key Features and Functions

Electric ball valves are gaining traction in industrial applications. Their design offers precision and reliability. But how do you choose the right one? Understanding key features is essential.

One crucial aspect is the material construction. Common materials include brass, stainless steel, and PVC. Each comes with unique strengths and weaknesses. For instance, PVC is lightweight and corrosion-resistant but may not withstand high pressures. In contrast, stainless steel is robust but heavier. Industry reports note that about 30% of failures arise from using incorrect materials.

Another key feature is the control mechanism. Electric ball valves can be modulating or on-off types. Modulating valves provide precise flow control, while on-off versions simply start or stop flow. Depending on your system's needs, selecting the appropriate type can prevent costly operational issues. Experts suggest that proper application analysis can reduce failures by up to 40%.

Tips: Consider the environmental conditions. Is your system exposed to extreme temperatures? Be mindful of how this impacts valve selection. Also, evaluate your electrical requirements. Mismatched power supplies can lead to dysfunction. Understanding these factors can enhance system performance.

Evaluating Flow Rate Requirements for Electric Ball Valve Selection

When selecting electric ball valves, understanding flow rate requirements is crucial. Flow rate determines how efficiently a system operates. According to industry reports, a mismatch can lead to inefficiencies or even system failure. Incorrectly sized valves may cause excess pressure drops or insufficient flow to critical components.

To evaluate flow rates, start by assessing your system’s specifications. Factors to consider include pipe diameter and fluid type. Common guidelines suggest balancing flow velocity between 3 to 8 feet per second for most applications. High flow rates can lead to erosion and noise. Low rates may cause sediment buildup or inadequate operation.

Also, consider operational conditions. Temperature and pressure can impact flow rates significantly. For instance, water behaves differently than oil at extreme temperatures. Ensure that your selected valve accommodates these variations. Involving engineering tools or software in calculations can provide more accuracy. These details matter. Ignoring them could result in costly redesigns down the line.

2026 How to Choose Electric Ball Valves for Your System? - Evaluating Flow Rate Requirements for Electric Ball Valve Selection

| Valve Size (inches) | Flow Rate (GPM) | Pressure Drop (psi) | Material | Operation Type |

| 1/2 | 15 | 2 | Brass | Electric |

| 3/4 | 30 | 3 | Stainless Steel | Electric |

| 1 | 50 | 4 | PVC | Electric |

| 1 1/2 | 75 | 5 | Bronze | Electric |

| 2 | 100 | 6 | Carbon Steel | Electric |

Assessing Voltage and Power Supply Considerations for Valves

When selecting electric ball valves, the voltage and power supply play crucial roles. The voltage should match the specifications of your system. Mismatched voltage can lead to malfunction or damage. Power supply stability is equally important. Variations can cause erratic behavior. Consistent power ensures reliable operation.

Tips: Always check the power supply ratings. Calculate the total wattage needed for all valves. Assess the installation environment too. If it's prone to fluctuations, consider using surge protectors.

Evaluate your system's compatibility with various voltage levels. Some valves work better with AC, while others prefer DC. Be aware of the power requirements for each type. This decision impacts efficiency and performance.

Tips: Keep an eye on power draw. High demand can affect other components in your system. Make sure your wiring can handle the load. Overlooking this could lead to costly repairs or replacements.

Sizing Electric Ball Valves: Determining Proper Dimensions and Specifications

Choosing the right size for electric ball valves is crucial. It affects system efficiency and performance. Sizing begins with understanding your application. What is the medium flowing through? Is it water, gas, or something else? Each has different requirements.

Next, consider the flow rate and pressure. These factors greatly influence the valve dimensions. Use a flow calculation to determine the size needed. An oversized valve can lead to issues like cavitation. If it’s too small, it may not handle the flow. Finding the sweet spot is essential.

Pay attention to installation space as well. Ensure there’s enough room for operation and maintenance. Not all systems allow for easy adjustments. Sometimes, a tight fit may lead to complications later. It’s worth measuring twice before deciding. Always consult your system specifications to avoid mishaps. With careful consideration, the right electric ball valve can significantly improve system performance.

2026 Electric Ball Valve Sizing Analysis

This chart illustrates flow rates for different sizes of electric ball valves from small to extra large. Proper sizing is crucial for ensuring optimal performance in your system.

Analyzing Materials and Construction for Reliability in Various Applications

When selecting electric ball valves, the choice of materials is crucial. The right materials determine the valve's longevity and compatibility with diverse applications. For example, valves made from stainless steel are known for corrosion resistance. They perform well in harsh environments. In contrast, PVC valves suit less aggressive applications. Each material has its strengths and limitations. For example, PVC is lightweight and easy to install but not ideal for high-temperature scenarios.

Reliability in construction is also vital. A well-made valve withstands pressure fluctuations. It reduces the risk of failures. A report by the American Society of Mechanical Engineers highlights that improperly constructed valves can lead to system breakdowns. In fact, over 30% of valve failures are attributed to material weaknesses and poor construction quality. This emphasizes the need for thorough testing. Manufacturers should conduct rigorous quality checks to ensure consistent performance.

Moreover, the operating environment should influence your choice. Some materials degrade under UV light, while others may not handle extremes in temperature. An analysis from Valin Corporation advocates matching the material properties with the specific application. A thoughtful selection process leads to better efficiency and fewer maintenance costs. It’s essential to reflect on these aspects to ensure optimal performance and reliability.