Identifying Issues with Small Robotic Arm Solutions for Global Buyers

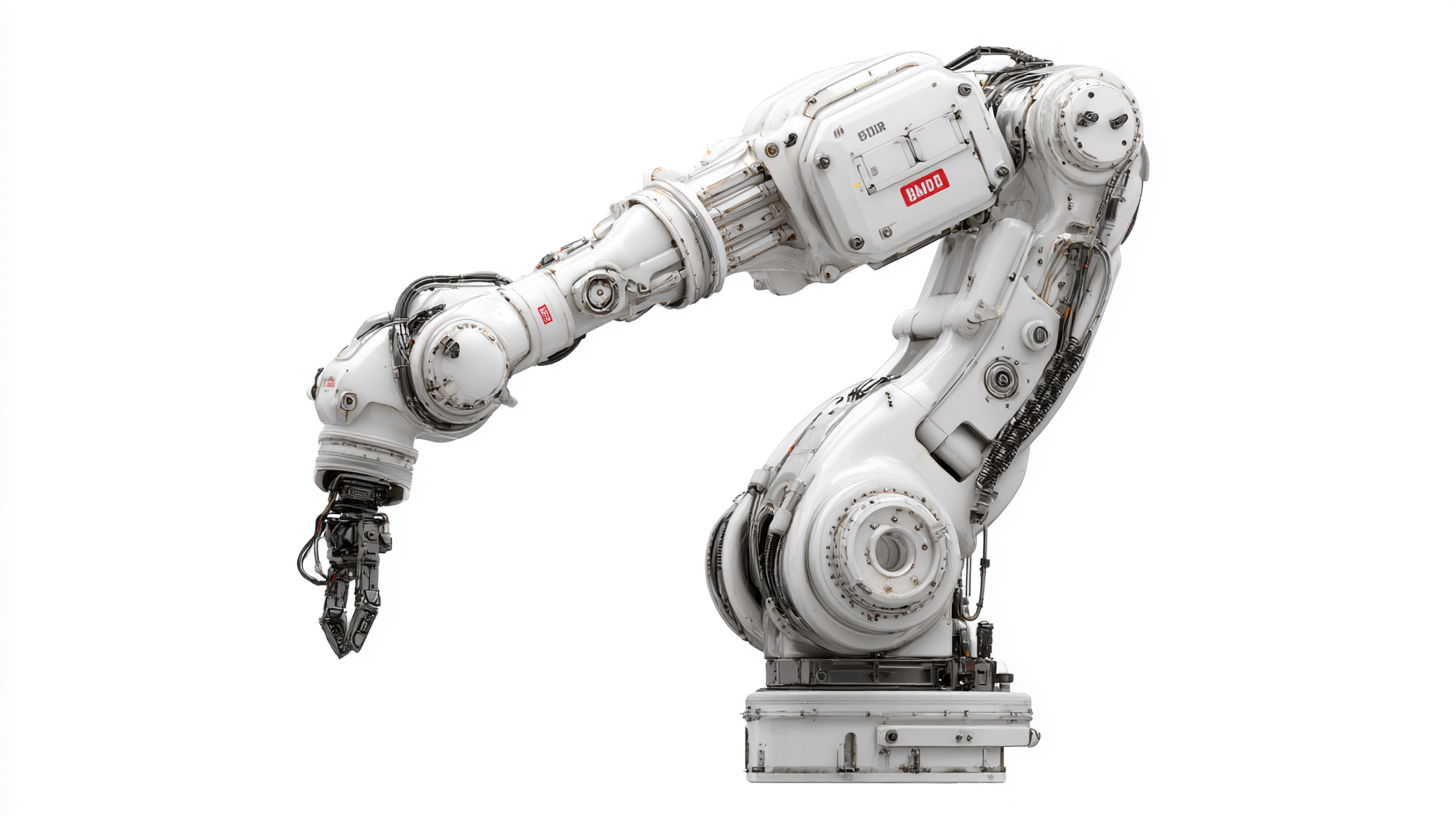

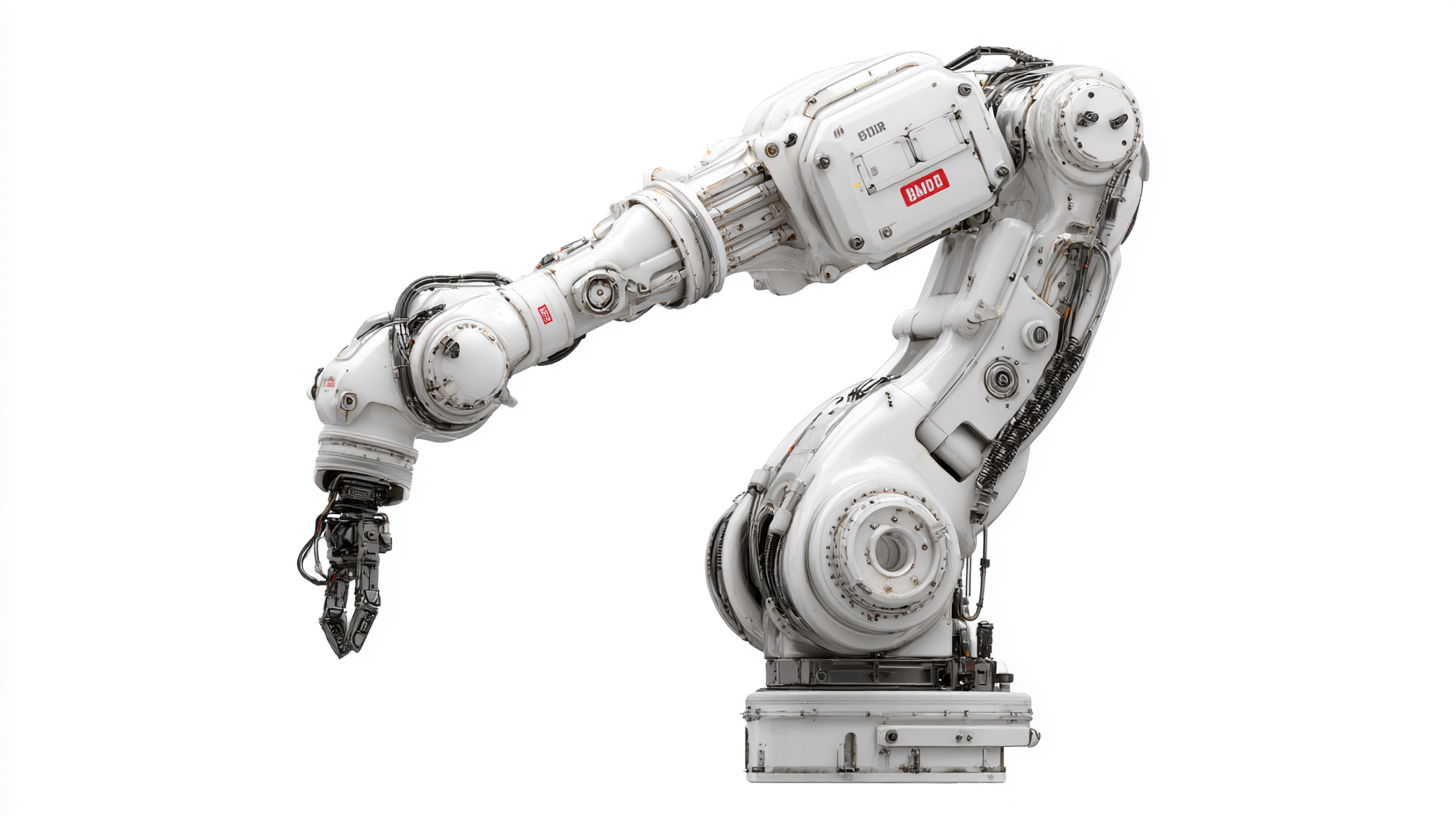

In the rapidly evolving field of automation, the demand for Small Robotic Arm solutions has surged among global buyers, ranging from small businesses to large enterprises. However, selecting the right manufacturer for these sophisticated devices can be a daunting task. With a plethora of options available, potential buyers often face challenges such as discerning quality, reliability, and support services offered by manufacturers. This blog will delve into the crucial issues faced in identifying high-quality Small Robotic Arm solutions, providing insights on how to navigate the selection process effectively. By focusing on key considerations such as technological advancements, customization capabilities, and post-purchase support, we aim to equip buyers with the knowledge necessary to make informed decisions that will enhance their operational efficiency and productivity.

Whether you are a newcomer to automation or looking to upgrade your existing robotics solutions, understanding these factors is vital to ensuring your investment yields the best possible results.

Challenges Faced by Global Buyers in Small Robotic Arm Acquisition

Acquiring small robotic arms presents numerous challenges for global buyers striving to enhance operational efficiency and automation. One of the primary hurdles is the diversity of specifications and technologies available in the market. Buyers often struggle to identify which robotic arms best meet their specific needs, as the variations in payload capacities, reach, and programming capabilities can be overwhelming. Furthermore, differing industry standards across regions complicate the purchasing process, as buyers must ensure compatibility with existing systems and regulatory requirements.

Another critical issue lies in the supply chain dynamics and post-purchase support. International buyers frequently face delays in delivery due to logistics constraints and varying lead times among manufacturers. This uncertainty can disrupt project timelines and impede the integration of robotic solutions. In addition, the availability of technical support and maintenance services can vary significantly by location, leading to potential downtime and increased operational risks. As companies navigate these complexities, establishing reliable partnerships with manufacturers and distributors becomes essential to mitigate risks and ensure a seamless acquisition experience.

Challenges Faced by Global Buyers in Small Robotic Arm Acquisition

Key Features of Chinese-Made Robotic Arms That Attract Global Market Interest

Chinese-made robotic arms are garnering significant attention in the global market due to their competitive features and advancements in technology. As the robotics industry evolves, these robotic arms demonstrate a blend of affordability, efficiency, and adaptability, making them appealing options for businesses, especially in sectors such as manufacturing and logistics. The incorporation of AI and machine learning capabilities enhances their operational efficiency, enabling them to perform a variety of tasks with minimal human intervention.

Furthermore, the surge in interest surrounding China's efforts to develop humanoid robots plays a crucial role in this trend. With companies leveraging existing supply chains and technical expertise, they are positioned to innovate rapidly, thus attracting global consumers. These advancements in robotics not only highlight China's growing technological prowess but also signify a shift towards more sophisticated robotic solutions that prioritize embodied intelligence. As international buyers explore options, understanding these key features will be essential in making informed decisions about integrating robotic arms into their operations.

Comparative Analysis: Chinese Robotic Arms vs. Competitors in Performance

In the rapidly evolving landscape of robotics, small robotic arms have gained significant attention from global buyers for their versatility and efficiency in various applications, from manufacturing to healthcare. A recent report by the International Federation of Robotics (IFR) highlights that the global market for industrial robots is expected to reach $60 billion by 2025, with small robotic arms leading the charge due to their compact design and ease of integration into existing workflows.

When comparing Chinese robotic arms to their international competitors, performance metrics such as speed, precision, and payload capacity reveal a nuanced landscape. According to a study by MarketsandMarkets, Chinese manufacturers have made remarkable strides, with robotic arms achieving over 90% of the precision levels of leading brands at half the cost. However, they often fall short in software integration and user support, which are critical for seamless operation in complex applications. This comparative analysis underscores the need for buyers to weigh not just the initial investment but also long-term operational support and performance reliability when selecting their robotic solutions.

Understanding Quality Control in Chinese Robotic Arm Manufacturing

The manufacturing of robotic arms in China is undergoing a significant transformation, marked by a heightened focus on quality control. As showcased at CES 2024, Chinese companies are making strides in delivering advanced humanoid robots, thus emphasizing the need for stringent manufacturing standards. A shift towards more refined quality control systems is imperative, particularly as the global market for smart robots is projected to grow from approximately $15.65 billion in 2025 to over $96.75 billion by 2033, reflecting a robust compound annual growth rate of 25.57%.

The manufacturing of robotic arms in China is undergoing a significant transformation, marked by a heightened focus on quality control. As showcased at CES 2024, Chinese companies are making strides in delivering advanced humanoid robots, thus emphasizing the need for stringent manufacturing standards. A shift towards more refined quality control systems is imperative, particularly as the global market for smart robots is projected to grow from approximately $15.65 billion in 2025 to over $96.75 billion by 2033, reflecting a robust compound annual growth rate of 25.57%.

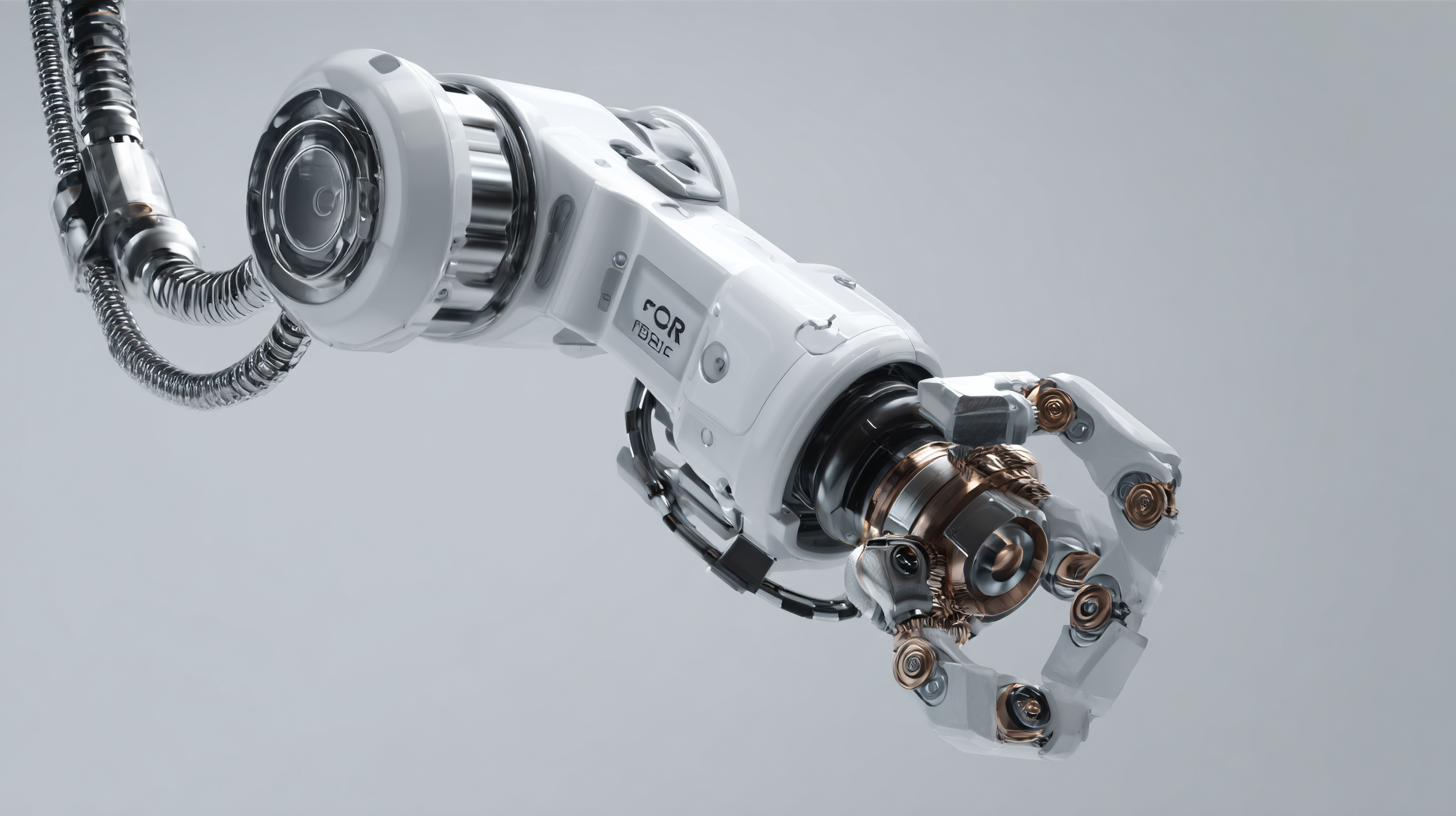

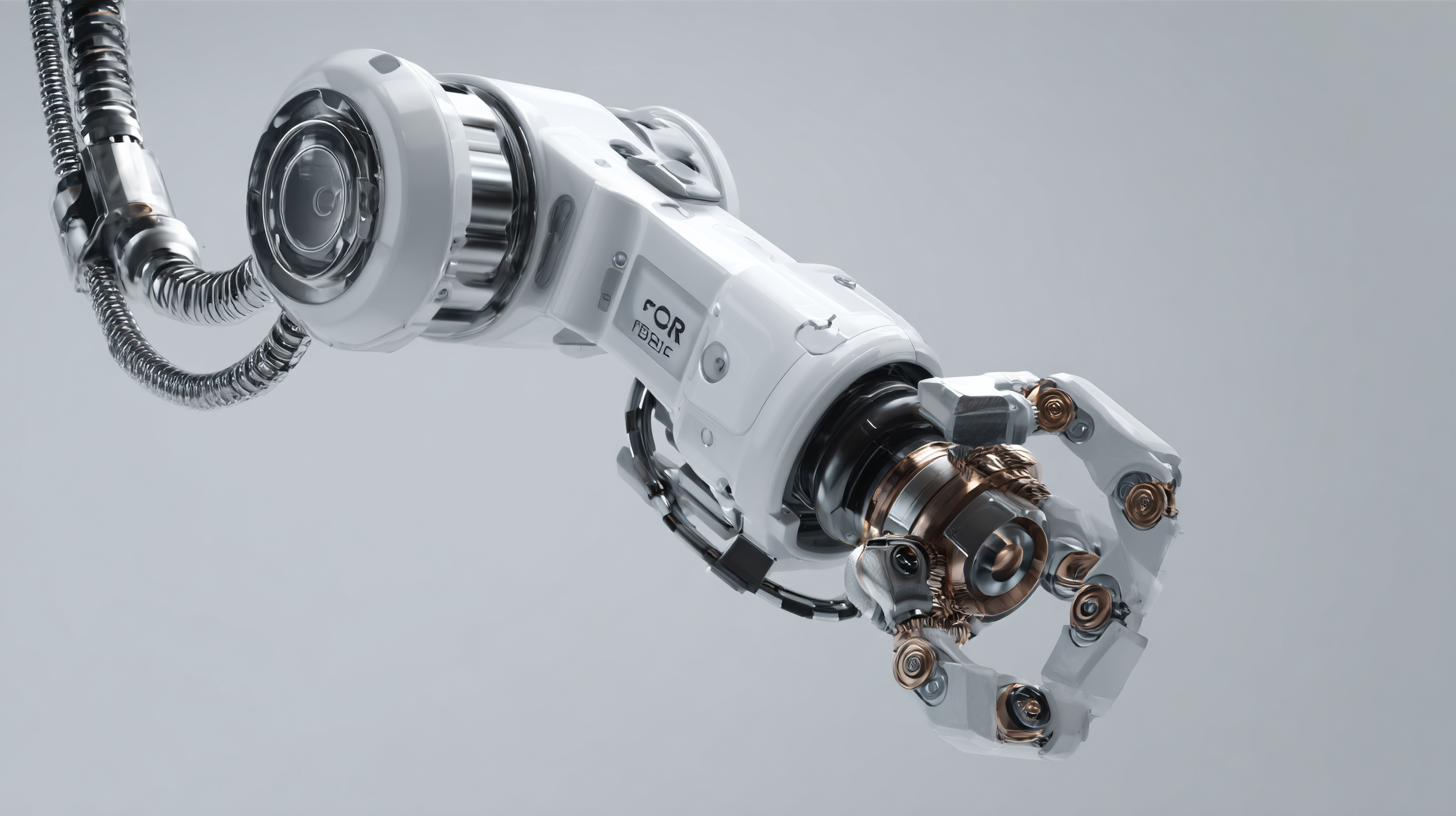

In the pursuit of excellence, robotic manufacturers must confront several challenges, including the standardization of components and the integration of advanced technologies. Companies are increasingly investing in AI-driven quality assurance processes. For instance, intelligent factories are emerging where robotic arms collaborate closely with AI vision systems to ensure that every aspect of the production meets high-quality benchmarks. As the humanoid robot industry expands, companies must not only focus on innovation and speed of development but also ensure that quality control measures evolve in tandem with their growing capabilities.

Future Trends in Robotic Arm Technology and Global Supply Chain Adaptation

The future of robotic arm technology is witnessing rapid advancements that reflect broader trends in supply chain adaptation. As businesses increasingly rely on automation and robotics, the integration of intelligent systems is reshaping logistics and warehouse operations. Key innovations such as automated storage and retrieval systems (AS/RS) and intralogistics robots are crucial in building more resilient supply chains that can efficiently meet evolving consumer demands.

Tips for companies looking to leverage robotic arm solutions include conducting thorough feasibility assessments to identify specific logistics needs, and investing in training programs to help staff adapt to new technologies. Emphasizing flexibility in robotic solutions can also enhance adaptability, ensuring that businesses can smoothly transition amid market fluctuations.

Continuous advancements in AI, sensing, and automation technologies are expected to propel industrial robotics further. With emerging trends such as indoor mobile robots and stationary robots gaining traction, companies must stay informed and agile. Investing in data analytics will be key to improving operational efficiency and anticipating changes in supply chain dynamics.

The manufacturing of

The manufacturing of