Why Do Rubber Pump Impellers Matter in Fluid Dynamics?

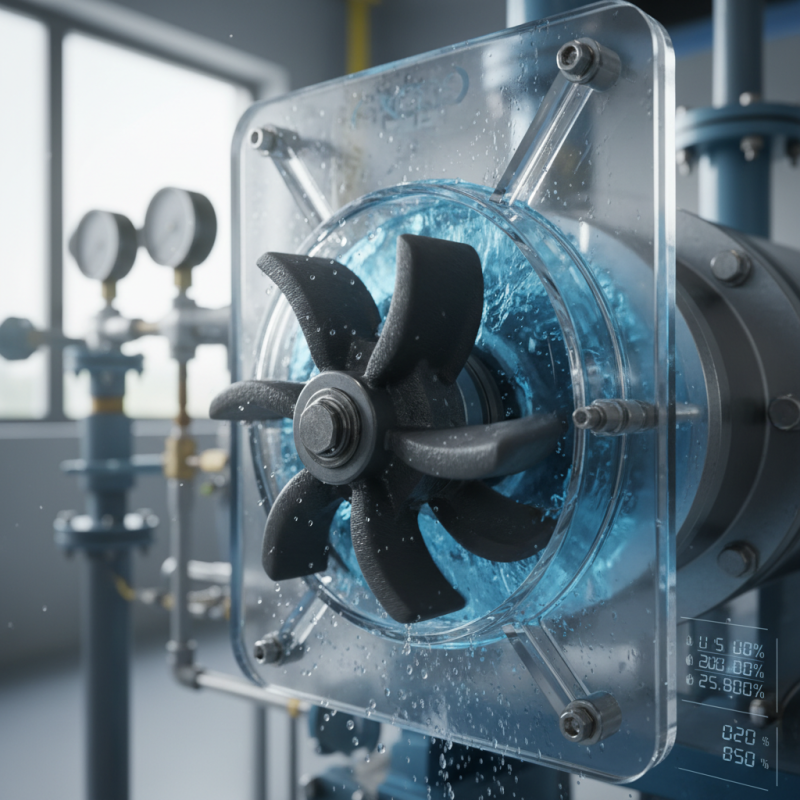

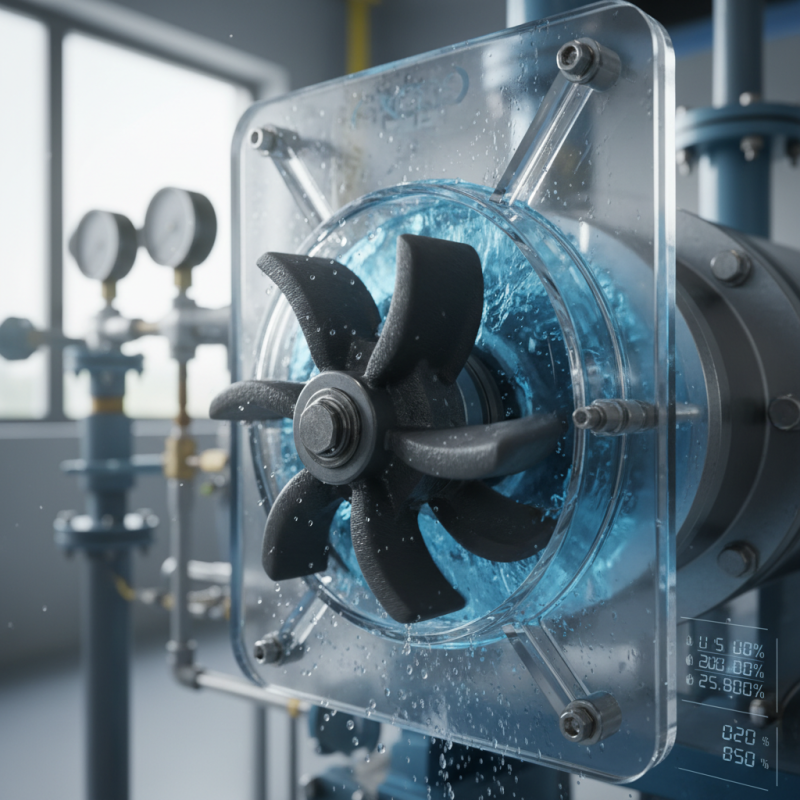

In the realm of fluid dynamics, the importance of the Rubber Pump Impeller cannot be overstated. This component plays a critical role in determining the efficiency and reliability of pumps across various industries. According to a Recent Market Research Report, the global rubber pump impeller market is projected to grow by 5% annually, highlighting its increasing significance. Industry expert Dr. Maria Chen states, "The performance of a rubber pump impeller can drastically influence fluid transport efficiency." Her insights underscore the need for quality materials and designs.

Rubber pump impellers are engineered to withstand harsh conditions while providing optimal flow rates. They are essential in sectors such as mining, agriculture, and water treatment. However, many operators underestimate the implications of poorly designed impellers. A subpar impeller not only affects performance but can lead to costly downtimes. As noted in the Journal of Fluid Mechanics, an inefficient rubber pump impeller can increase energy consumption by up to 30%. These factors compel us to reevaluate current designs and materials in pursuit of enhanced performance and sustainability.

In conclusion, understanding the role of rubber pump impellers in fluid dynamics is vital. As industries evolve, so must the designs and technologies associated with these crucial components. Failing to address these gaps could hinder operational efficiency and escalate costs.

The Fundamental Role of Impellers in Fluid Dynamics

Impellers are crucial in fluid dynamics. They enhance the movement of fluids in various applications, such as pumps and turbines. A well-designed impeller increases efficiency, reduces energy consumption, and minimizes maintenance costs. According to industry reports, optimizing impeller design can improve pump performance by up to 30%. This efficiency translates into significant savings for industrial operations.

Tip: Regularly inspect impellers for wear and tear. Small damages can lead to larger inefficiencies over time.

The choice of materials for impellers is essential. Rubber, in particular, can offer flexibility and resistance to corrosion. This is vital in applications involving aggressive fluids. Data shows that rubber impellers can last 20% longer than their metal counterparts in specific environments. However, not every fluid application is suitable for rubber. Understanding the fluid's properties is critical for selecting the right material.

Tip: Consider the fluid's temperature and chemical compatibility when choosing impeller materials. Missteps can result in premature failure.

Understanding the Composition of Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid dynamics. Their composition and design impact performance significantly. Typically, these impellers consist of synthetic or natural rubber, selected for its elasticity and resilience. A report from the Fluid Handling Manufacturers Association notes that materials like EPDM rubber can endure temperatures from -40°F to 300°F, demonstrating wide applicability.

The flexibility of rubber allows for efficient fluid movement. In many cases, rubber impellers can reduce vibration and noise during operation. A study by the American Society of Mechanical Engineers reveals that pumps using rubber impellers perform up to 30% better in high-viscosity fluids compared to their rigid counterparts. This characteristic is essential in industries requiring precise fluid transfer.

However, durability can be a concern. Over time, rubber can degrade due to environmental factors like UV exposure or chemicals. Industry surveys indicate that maintenance costs for rubber impeller pumps can exceed 15% of their initial investment, particularly if not regularly monitored. Understanding these dynamics is crucial for effective pump selection and management.

Comparison of Rubber Pump Impeller Material Properties

This bar chart illustrates the tensile strength of various rubber pump impeller materials. Understanding the differences in their mechanical properties is crucial for selecting the appropriate impeller for specific fluid dynamics applications.

Mechanisms of Fluid Movement Driven by Impellers

In fluid dynamics, impellers play a crucial role in moving fluids efficiently. Rubber pump impellers are versatile. They provide flexibility and strength. This adaptability can lead to improved flow rates. The design of these impellers affects how fluid moves inside the pump.

Different impeller shapes create various flow patterns. A closed impeller generates more pressure, while an open design allows for easier handling of solids. Yet, the balance between these designs is often neglected. Incorrect choices can lead to inefficiencies. For example, using closed impellers in slurry applications might cause clogging.

Understanding how impellers interact with fluid is vital. Poorly designed systems can lead to cavitation. This destructive phenomenon happens when pressure drops too low. It's crucial for engineers to consider these factors during design. The implications of these choices are significant. Fluid dynamics is complex, and even small adjustments can yield major changes.

Why Do Rubber Pump Impellers Matter in Fluid Dynamics? - Mechanisms of Fluid Movement Driven by Impellers

| Impeller Type | Material | Efficiency (%) | Flow Rate (m³/h) | Head (m) |

| Open Impeller | Rubber | 85 | 150 | 25 |

| Closed Impeller | Rubber | 90 | 120 | 30 |

| Semi-Open Impeller | Rubber | 80 | 100 | 20 |

| Vortex Impeller | Rubber | 75 | 80 | 15 |

| Backward Inclined Impeller | Rubber | 88 | 140 | 28 |

Impact of Impeller Design on Pump Efficiency

When it comes to fluid dynamics, the design of rubber pump impellers plays a crucial role. The shape and material of an impeller can greatly influence a pump's efficiency. In many cases, a well-designed impeller maximizes flow rates while minimizing energy consumption. However, not all designs achieve this balance.

One common mistake is neglecting the impact of the impeller's geometry. For example, a poorly designed impeller may cause turbulence, reducing efficiency. This can lead to increased wear over time, ultimately affecting pump longevity. Experimentation with different shapes can yield surprising results.

Tips: Always consider the fluid's properties. A thick fluid may require a different design than a thin one. Additionally, regular maintenance and inspection are vital. Ensure your impeller remains in good condition to maintain performance. Remember, sometimes it’s the smallest changes that lead to significant improvements. Every design choice matters. Past experiences can guide new designs, but each application requires fresh thinking.

Adjusting parameters based on real-time feedback could reveal hidden potential.

Applications of Rubber Pump Impellers in Various Industries

Rubber pump impellers play a crucial role in various industries, ensuring the efficient movement of fluids. They are commonly used in water treatment, chemical processing, and food production. In water treatment, for instance, rubber impellers help manage wastewater effectively. According to industry reports, the global water treatment market is projected to reach $1 trillion by 2025. This highlights the need for reliable pump components.

In chemical processing, rubber impellers are favored for their resistance to corrosion and abrasion. They can handle a wide range of chemicals, which is vital for safety and efficiency. A study found that using rubber impellers can reduce downtime by 15%, significantly impacting production schedules. However, improper material selection can lead to failures. It is essential to assess the fluid characteristics before choosing the right impeller.

Food production also benefits from rubber pump impellers. These impellers can withstand frequent cleaning cycles, maintaining hygiene standards. The market for food processing equipment reached $1.1 billion in 2021. With rubber components, companies can ensure product integrity and reduce contamination risks. Despite their advantages, companies should remain vigilant about wear and tear, evaluating their equipment regularly.