Unveiling the Top 5 Specifications of the Best Collaborative Robots for Enhanced Productivity

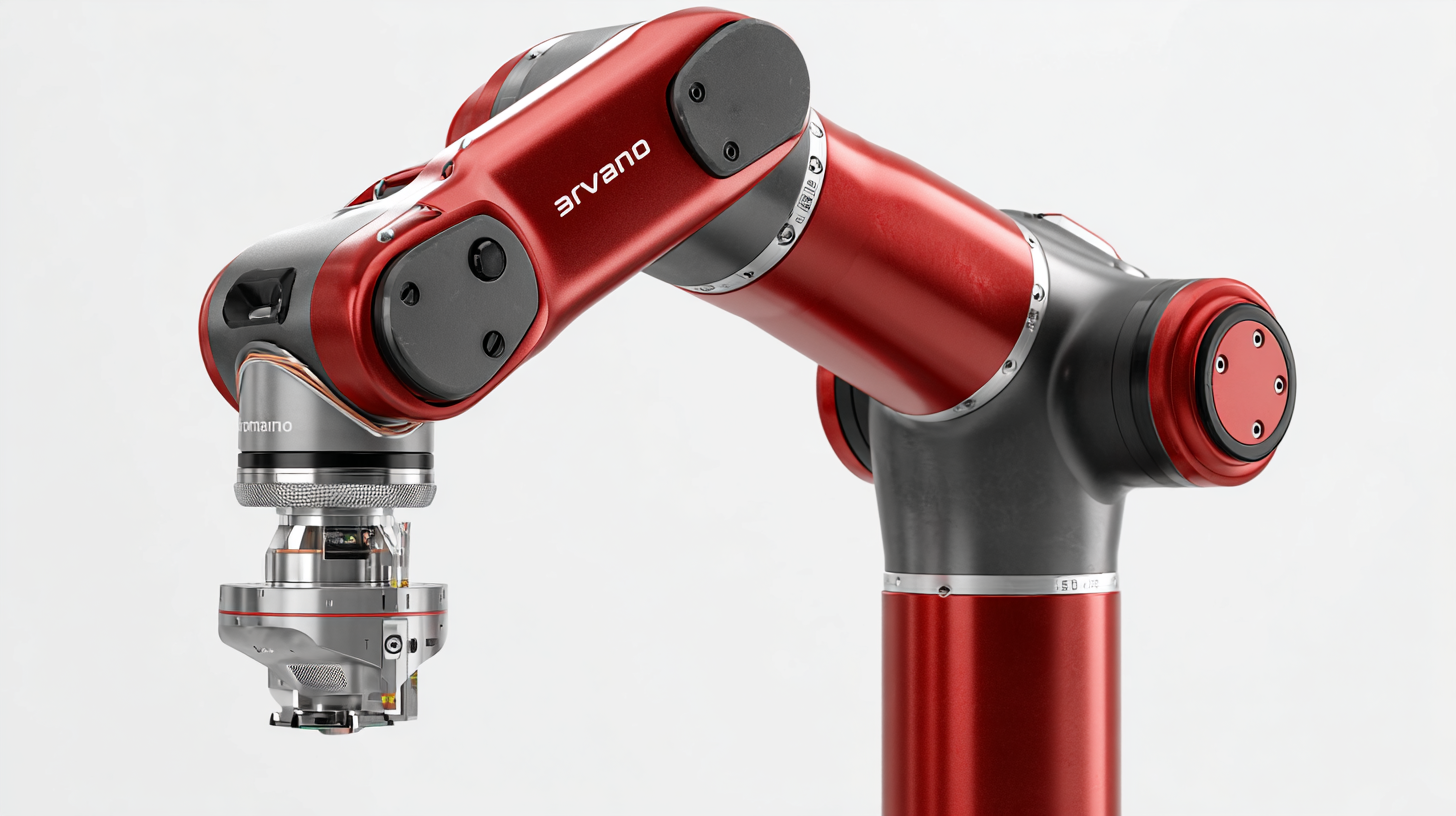

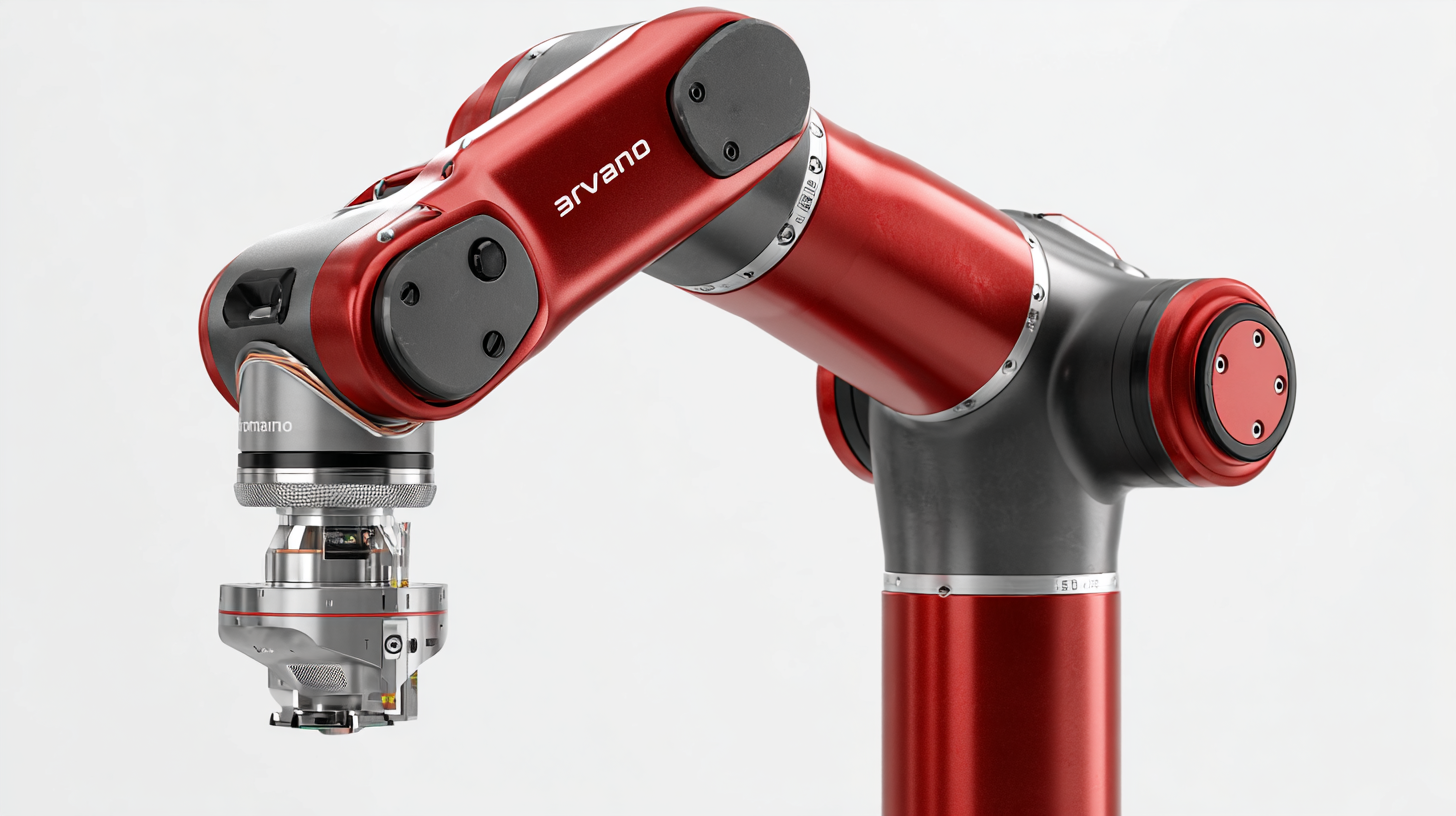

In today's rapidly evolving manufacturing landscape, the integration of

Collaborative Robots (cobots) has become a game-changer for

businesses seeking enhanced productivity and efficiency. Unlike traditional industrial robots,

cobots are designed to work alongside human operators, complementing their skills and adapting to

their needs. This unique collaboration not only streamlines workflows but also fosters a

safer working environment by minimizing the risk of injury

in high-demand settings. In this blog, we will unveil the top five specifications that define the

best collaborative robots on the market today. Understanding

these key features is essential for businesses looking to harness the full potential of cobots,

ultimately leading to increased operational efficiency and improved competitive advantage in an

increasingly automated world. Join us as we explore how adopting the right collaborative robots

can transform your production processes and elevate workplace productivity.

Key Specification 1: Advanced Sensing Technology for Enhanced Safety and Interaction

In the rapidly evolving world of automation, the integration of

advanced sensing technology within collaborative robots (cobots)

is revolutionizing workplace safety and efficiency. One of the standout features that defines the

best collaborative robots today is their ability to perceive and respond to their environment

with exceptional precision. This advanced sensing technology includes a combination of vision

systems, proximity sensors, and force feedback mechanisms that enable cobots to detect human

presence and obstacles in real-time. As a result, they can operate safely alongside human workers,

significantly reducing the risk of accidents while fostering a

collaborative working environment.

Moreover, enhanced interaction capabilities are a game-changer

for productivity. Robots equipped with sophisticated sensing technology can interpret human gestures,

vocal commands, and even analyze emotional cues, allowing for more intuitive human-robot collaboration.

This capability not only streamlines workflow but also increases overall operational efficiency.

For instance, in assembly lines or logistics, cobots can seamlessly adjust their actions based on

human operators, ensuring that tasks are completed faster and with higher accuracy.

Ultimately, the integration of advanced sensing technology in collaborative robots is not just about

safety; it’s about transforming the way we work together in a

shared space.

Key Specification 2: Flexible Payload Capacity for Diverse Applications

In today's rapidly evolving production environment, flexible payload capacity has emerged as a crucial specification for collaborative robots, or cobots. This adaptability allows these robots to handle a range of tasks, accommodating various weights and shapes of materials. Companies often encounter diverse applications, from intricate assembly processes to heavy lifting, and the ability of a cobot to adjust its payload capacity accordingly can significantly enhance operational efficiency.

For instance, a collaborative robot equipped with a flexible payload capacity can seamlessly switch between lightweight components in delicate assembly tasks and heavier parts in more robust manufacturing processes. This versatility reduces downtime and the need for multiple specialized robots, leading to cost savings and increased throughput. Additionally, as industries continue to embrace automation, the capability to work with different payloads ensures that cobots can be integrated into existing workflows with minimal disruption, fostering a more productive and agile manufacturing environment.

Key Specification 3: User-Friendly Programming Interfaces for Quick Deployment

In the ever-evolving landscape of automation, the effectiveness of collaborative robots—often termed cobots—largely hinges on their programming capabilities. A user-friendly programming interface is essential as it enables operators, regardless of their technical background, to quickly deploy and tune the robots for specific tasks. This flexibility not only reduces downtime but also accelerates the integration of cobots into existing workflows, ultimately enhancing productivity.

For organizations seeking to maximize the benefits of collaborative robots, prioritizing systems with intuitive programming tools is crucial. These interfaces often feature drag-and-drop functionality, simplifying the process of task assignment. Additionally, many advanced cobot platforms provide comprehensive tutorials and real-time support, allowing users to troubleshoot issues without extensive training.

When selecting a collaborative robot, consider looking for pre-built templates that cater to common applications within your industry. This can significantly cut down on setup time and allow operators to focus on optimizing performance rather than grappling with complex coding. Also, look for user communities or forums associated with your cobot choice, as peer support can be an invaluable resource for overcoming unique challenges and sharing best practices.

Key Specification 4: Collaborative Features for Seamless Human-Robot Interaction

In today's rapidly evolving industrial landscape, the integration of

collaborative robots, or cobots, has become crucial for enhancing productivity. One key specification that

distinguishes the best collaborative robots is their collaborative features, which facilitate seamless human-robot interaction.

According to a report by the International Federation of Robotics, the global cobot market is projected to grow significantly,

with a compound annual growth rate of 50% anticipated over the next five years. This highlights the

necessity for designs that prioritize safety and efficiency in collaborative environments.

Effective human-robot interaction hinges on various features, such as

advanced sensory technologies and intuitive programming interfaces. Cobots

equipped with vision systems and force feedback allow for

real-time adjustments, making them capable of safely coexisting with human workers.

A study by ABI Research indicates that about 57% of manufacturers believe that enhancing worker

collaboration with robots will lead to increased operational efficiency. By focusing on collaborative features, companies can not only ensure the

safety of their workforce but also streamline workflows, ultimately making their operations more productive and competitive in a

technology-driven market.

Key Specification 5: Real-Time Data Analytics for Continuous Productivity Improvement

In today’s fast-paced industrial landscape, real-time data analytics has emerged as a crucial specification for collaborative robots (cobots), driving continuous productivity improvement across various sectors. According to a report by McKinsey, companies that leverage real-time data analytics can enhance their productivity by up to 20-25%. This improvement stems from the ability of cobots to instantly process and analyze operational data, enabling manufacturers to make informed decisions quickly and efficiently.

Furthermore, the integration of real-time data analytics allows for predictive maintenance and immediate troubleshooting, resulting in minimized downtime. A study conducted by Deloitte revealed that organizations using advanced analytics could potentially reduce equipment failure rates by 30%. This capability not only boosts operational efficiency but also significantly cuts costs associated with unscheduled maintenance. As businesses increasingly adopt collaborative robots equipped with sophisticated data analytics capabilities, they are poised to stay competitive in the evolving marketplace, ultimately fostering a culture of continuous improvement and agility.