How to Transform Your Manufacturing Process with Robotic CNC Machines: Key Benefits and Insights

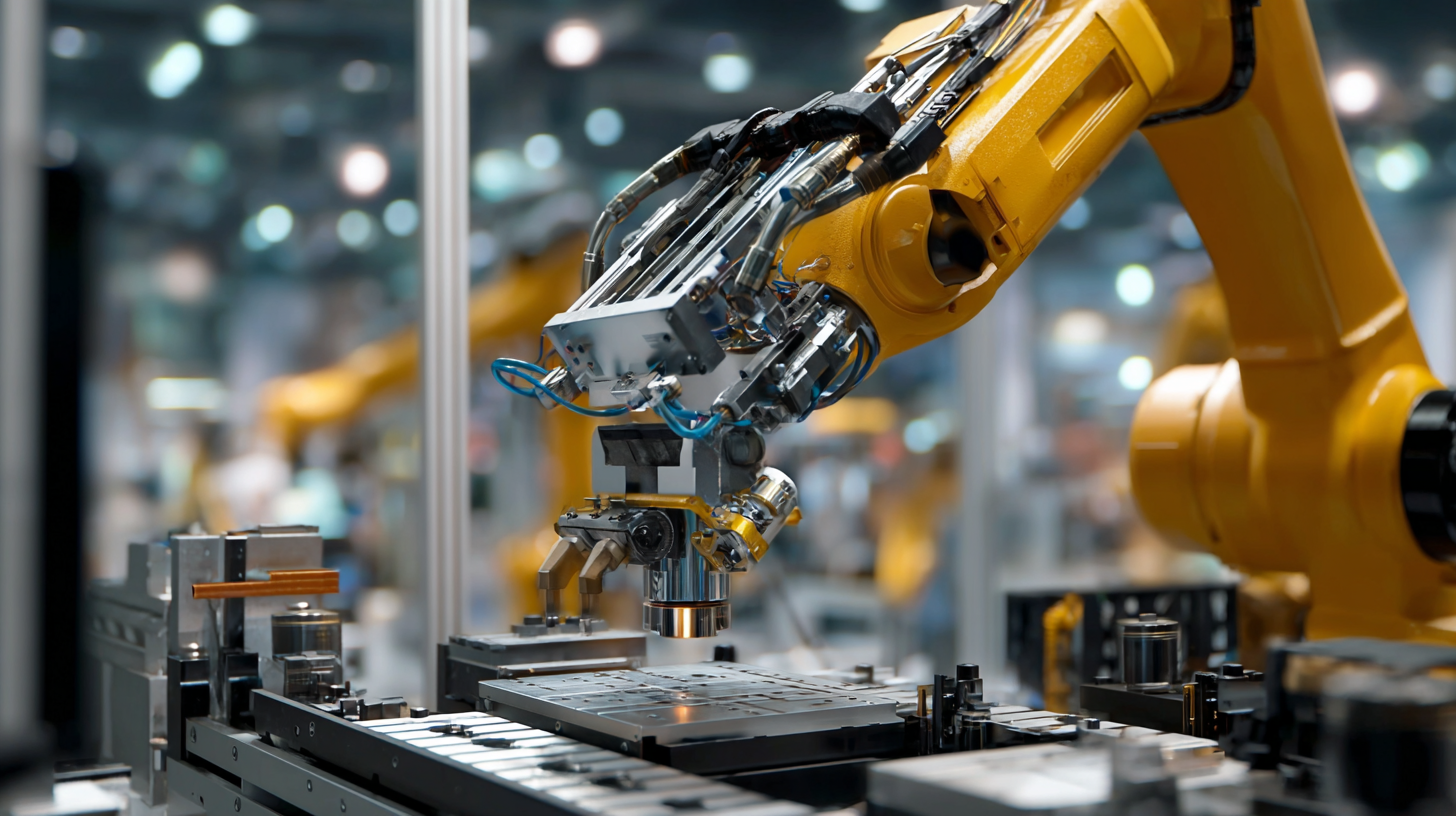

In recent years, the manufacturing landscape has witnessed a significant transformation driven by advancements in

automation and robotics. The integration of

Robotic CNC Machines into production lines has revolutionized

the way manufacturers operate, offering unprecedented precision and efficiency. According to a report by the

International Federation of Robotics,

global sales of industrial robots, including CNC machines, have surged by over 12%

annually, highlighting the growing reliance on automation in manufacturing processes. Furthermore, a study from the

McKinsey Global Institute suggests

that adopting robotic technologies can increase productivity by up to 30% while reducing

operational costs by 20%.

By leveraging the capabilities of Robotic CNC Machines,

manufacturers can enhance their competitive edge, streamline operations, and adapt to the ever-evolving demands of the market.

This article delves into the key benefits and insights that come from transforming manufacturing processes with these advanced technologies.

Benefits of Implementing Robotic CNC Machines in Modern Manufacturing

The implementation of robotic CNC machines in modern manufacturing brings forth a multitude of benefits that enhance productivity and precision. One of the primary advantages is increased efficiency; robotic systems can operate continuously without breaks, significantly reducing downtime associated with manual labor. This results in a higher output rate and the ability to meet growing demands in various industry sectors. Moreover, robotic CNC machines can execute complex tasks with remarkable speed and accuracy, which minimizes errors and maximizes the quality of the finished products.

Another significant benefit is the improved safety of the working environment. By delegating hazardous tasks to robots, manufacturers can protect their workforce from potential injuries associated with heavy machinery and repetitive tasks. This shift not only enhances employee morale but also complies with workplace safety regulations. Additionally, the integration of robotic systems allows manufacturers to optimize their production processes, enabling them to adapt swiftly to market changes and customer demands. Overall, the adoption of robotic CNC machines positions manufacturers for success in a competitive landscape.

Impact of Robotic CNC Machines on Manufacturing Efficiency

Key Strategies for Integrating Robotic CNC Technology into Existing Systems

Integrating robotic CNC technology into existing manufacturing systems presents a transformative opportunity to enhance productivity and precision. One key strategy involves conducting a thorough assessment of current processes to identify areas where automation can deliver the greatest impact. This assessment should focus on identifying repetitive tasks and bottlenecks, enabling manufacturers to pinpoint which operations can benefit most from robotic intervention.

Additionally, training and development play a crucial role in the successful implementation of robotic CNC machines. Engaging your workforce with comprehensive training programs not only ensures a smoother transition but also fosters a culture of innovation and adaptability. Encouraging collaboration between robotics engineers and machine operators can help bridge the knowledge gap, enabling teams to optimize the integration of robotic technology effectively. This proactive approach ultimately leads to improved operational efficiency and reduced downtime, setting the stage for a more agile manufacturing environment.

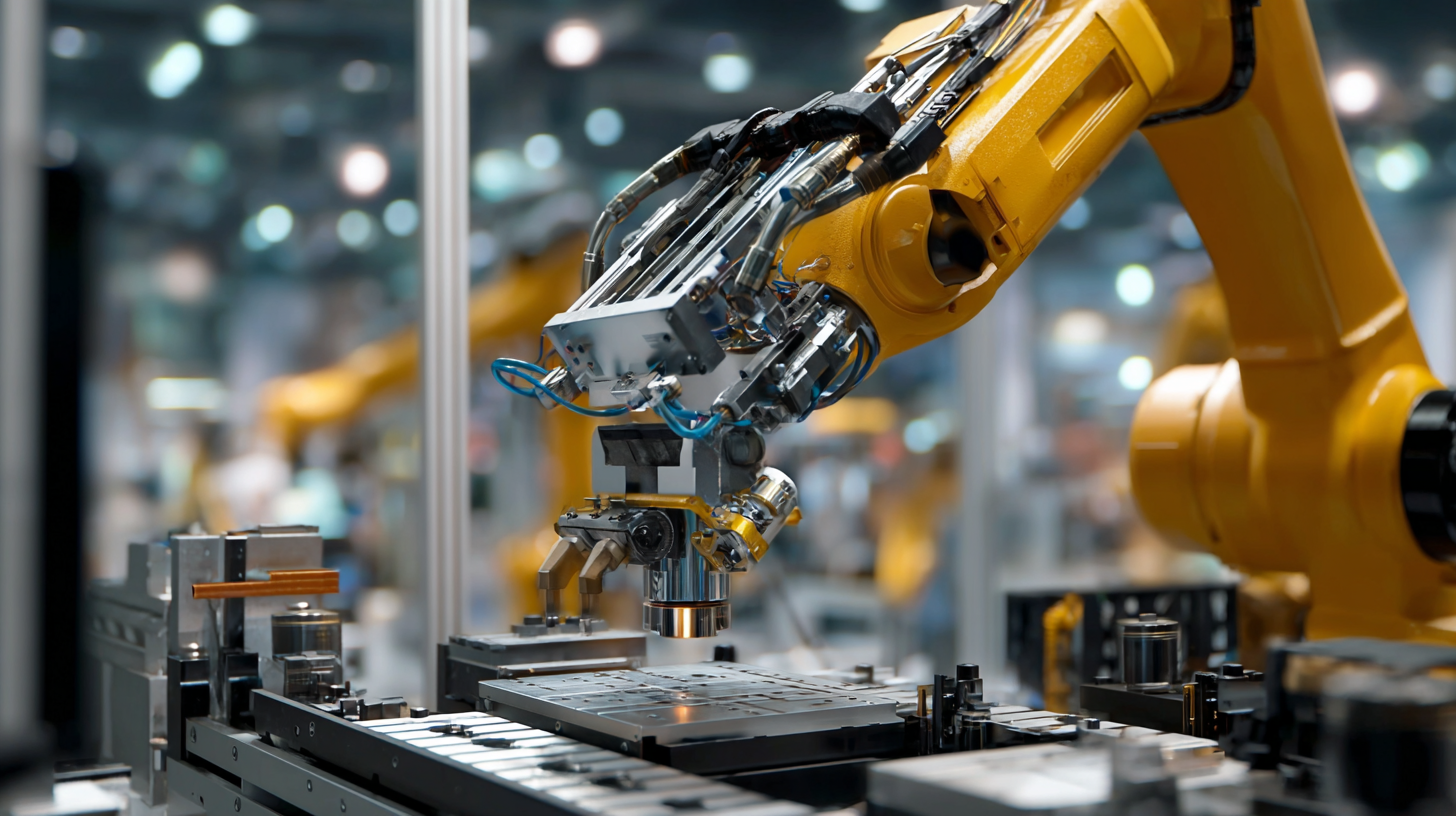

Impact of Robotic CNC Machines on Production Efficiency and Cost Reduction

The adoption of robotic CNC machines in manufacturing has proven to significantly enhance production efficiency while driving down costs. According to a report by the International Federation of Robotics, industries employing robotic systems have seen productivity increases of up to 30%. This uptick is attributed to the machines' ability to operate continuously, minimizing downtime and maximizing output. Additionally, with precision machining capabilities, robotic CNC machines help reduce material waste by up to 25%, allowing manufacturers to allocate their resources more effectively.

Tips: To maximize efficiency when integrating robotic CNC machines, it’s essential to start with a comprehensive analysis of your existing processes. Identify bottlenecks and areas where automation could be beneficial. Schedule regular maintenance to ensure machines operate at peak performance and avoid costly breakdowns.

Furthermore, the financial implications of switching to robotic CNC technology are staggering. A McKinsey report highlights that companies can expect to lower their operational costs by approximately 20-50% after implementing automated systems. This is largely due to reduced labor costs and increased throughput. By investing in robotic CNC machines, manufacturers not only improve their competitive edge but also position themselves for sustainable growth in an increasingly automated future.

Tips: Consider phased implementation of robotic solutions to monitor the impact on your production line, allowing for adjustments and optimizing ROI. Training staff on machine handling and maintenance is crucial for a smooth transition and long-term success.

Emerging Trends in Robotic CNC Machinery and Their Market Insights

The landscape of manufacturing is rapidly evolving with the integration of robotic CNC machines, which is not only enhancing productivity but also paving the way for innovative trends in digital manufacturing. The global servo motors and drives market, pivotal components in robotic systems, is projected to reach a valuation of $21.44 billion by 2031, growing at an impressive compound annual growth rate (CAGR) of 5.8% from 2024 to 2031. This trend underscores the escalating demand for precision and efficiency in manufacturing processes facilitated by advanced robotics.

Additionally, the adoption of 5-axis CNC machining centers is anticipated to yield a substantial market growth, increasing by $792.5 million between 2024 and 2028. This surge is largely attributed to self-optimized cutting capabilities driven by artificial intelligence, which significantly streamlines operations and mitigates waste. Furthermore, the bending machine market is expected to grow from $9.5 billion in 2024 to an estimated $16.6 billion by 2034, reflecting a CAGR of 5.9%. These figures not only highlight the economic potential of robotic CNC machinery but also reflect the broader shifts toward automation and smart manufacturing.

How to Transform Your Manufacturing Process with Robotic CNC Machines: Key Benefits and Insights

| Feature |

Description |

Benefit |

Market Trend |

| Increased Precision |

Robotic CNC machines offer higher precision in manufacturing components. |

Reducing material waste and costs. |

Growing demand for high-quality products. |

| Automation |

Ability to automate repetitive tasks in the manufacturing process. |

Increased efficiency and reduced labor costs. |

Rising trend towards Industry 4.0 advancements. |

| Flexibility |

Easily adaptable machines able to switch between different tasks. |

Catering to custom orders efficiently. |

Shift towards personalized manufacturing. |

| Cost Savings |

Long-term savings through reduced labor and material costs. |

Higher profit margins for manufacturers. |

Increasing competition leading to cost reductions. |

| Data Integration |

Systems that gather and analyze production data in real-time. |

Enhanced decision making and process optimization. |

Emerging focus on smart manufacturing technologies. |

Case Studies: Successful Transformations with Robotic CNC in Manufacturing Industries

Robotic CNC machines are rapidly transforming the manufacturing landscape, offering a range of benefits that streamline processes and improve efficiency. Case studies in various industries reveal significant gains in productivity and quality. For instance, a study found that companies integrating robotic CNC technology observed a 30% increase in output and a 20% reduction in operational costs. These advancements allow manufacturers to minimize errors and maintain high precision, which is crucial in sectors such as aerospace and automotive.

Tips for implementing robotic CNC technology effectively include starting with a thorough assessment of existing workflows to identify areas for automation. Additionally, investing in training for employees to operate and maintain these machines can further enhance success rates. Research shows that organizations with a robust training program see a 25% increase in the effective utilization of their robotic systems.

Moreover, leveraging augmented reality (AR) in operational setups can provide an immersive training environment, improving understanding and skills without disrupting production. A modular-based approach using AR allows for flexible adaptations in manufacturing processes, optimizing both time and cost efficiency. Adopting these technologies not only fosters innovation but also positions companies at the forefront of the industry.