Transforming Industries: Real-World Examples of Cooperative Robots in Action

In today's rapidly evolving industrial landscape, the integration of technology is redefining productivity and efficiency. Central to this transformation are Cooperative Robots, or cobots, which are designed to work alongside humans in a shared workspace, enhancing both safety and productivity.

Unlike traditional industrial robots that operate in isolation, cooperative robots have the unique ability to collaborate with human workers, adapting to their movements and responding intuitively to their needs.

This blog will explore real-world examples showcasing the diverse applications of cooperative robots across various industries, highlighting their role in streamlining operations, improving workplace safety, and driving innovation.

From manufacturing floors to healthcare environments, we will delve into how these intelligent machines are not only enhancing human capabilities but also fostering a new era of collaboration between humans and machines.

Introduction to Cooperative Robots: The Future of Industry Collaboration

Cooperative robots, or cobots, are revolutionizing industrial collaboration by working alongside human operators to enhance productivity and safety. According to a recent report by the International Federation of Robotics, the global sales of cobots are expected to reach 1.7 million units by 2024, reflecting a staggering compound annual growth rate (CAGR) of 44%. This surge is driven by industries recognizing the advantages of integrating human intelligence and dexterity with robotic strength and efficiency.

In sectors like manufacturing, logistics, and healthcare, cobots are not just augmenting human efforts but are also redefining operational paradigms. For instance, a study from the Boston Consulting Group revealed that companies utilizing cobots reported an increase in productivity by 30% while simultaneously reducing workplace injuries by up to 50%. This alignment of human and robotic capabilities showcases a future where industries thrive on collaboration rather than competition, leading to enhanced outcomes across various processes. As organizations continue to adopt these advanced robotic solutions, the potential for innovation and operational excellence remains boundless.

Transforming Industries: Real-World Examples of Cooperative Robots in Action

This chart illustrates the various applications of cooperative robots across different industries, showcasing their contributions to productivity and efficiency. The data highlights the increase in adoption rates over recent years, reflecting the trend towards greater industry collaboration through robotics.

Understanding the Basic Functions and Benefits of Cooperative Robots

Cooperative robots, commonly known as cobots, are revolutionizing various industries by working alongside human operators to enhance productivity and efficiency. According to a report by the International Federation of Robotics, the global cobot market is expected to surpass $7 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 30%. This surge is largely attributed to the versatile applications of cobots, which can perform tasks ranging from assembly and welding to packaging and inspection, often in sectors such as manufacturing, logistics, and healthcare.

One of the primary functions of cooperative robots is to assist in repetitive and physically demanding tasks. For instance, cobots equipped with advanced sensors and artificial intelligence can adapt to their operational environment, ensuring safety and efficiency while collaborating with humans. A study by Deloitte highlighted that implementing cobots can increase productivity by up to 30% while reducing workplace injuries. This not only leads to better worker satisfaction but also optimizes production lines, making workplaces safer and more efficient. The benefits of cooperative robots are clear; they are transforming industries by facilitating a harmonious coexistence between human skills and robotic precision.

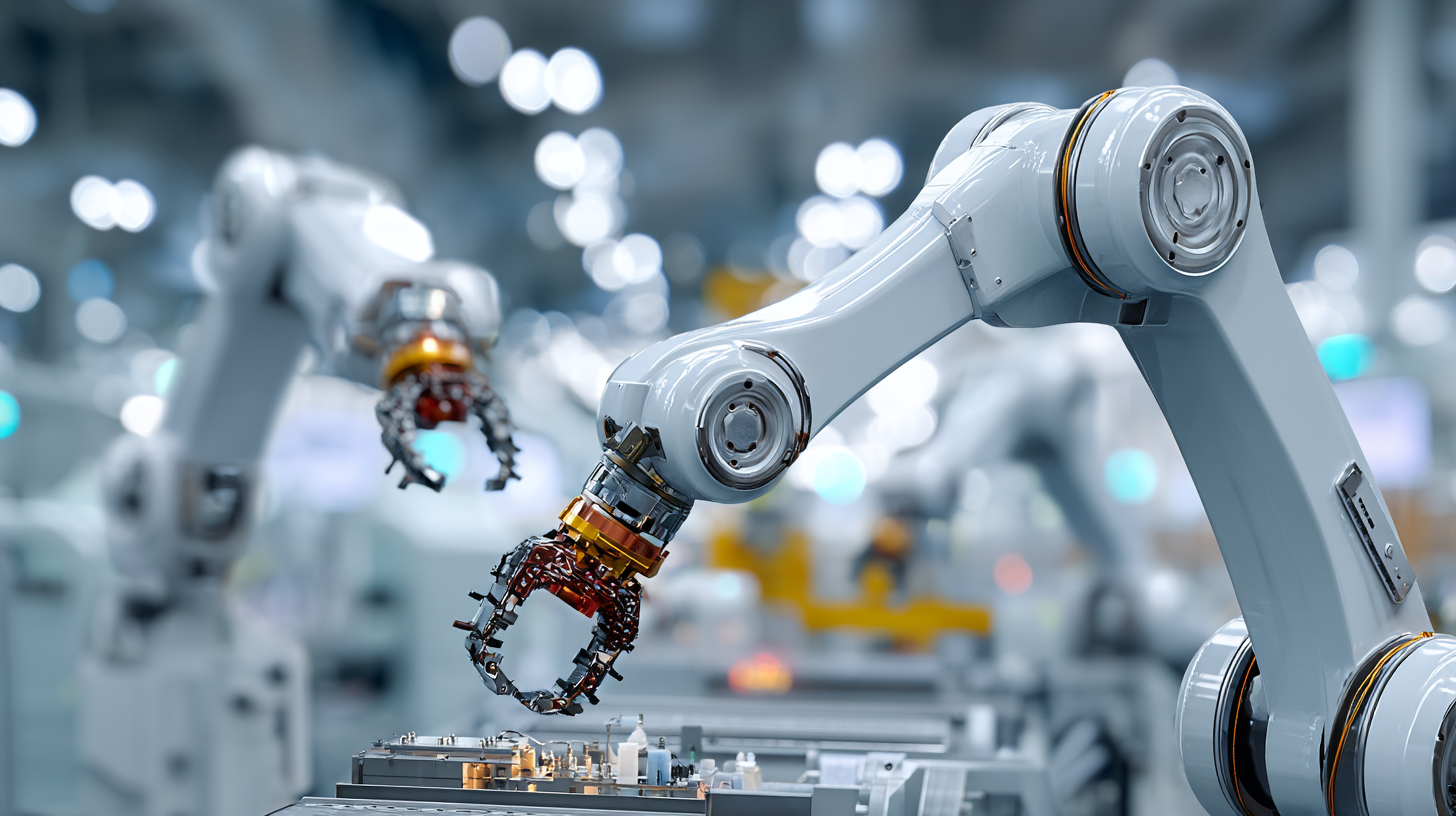

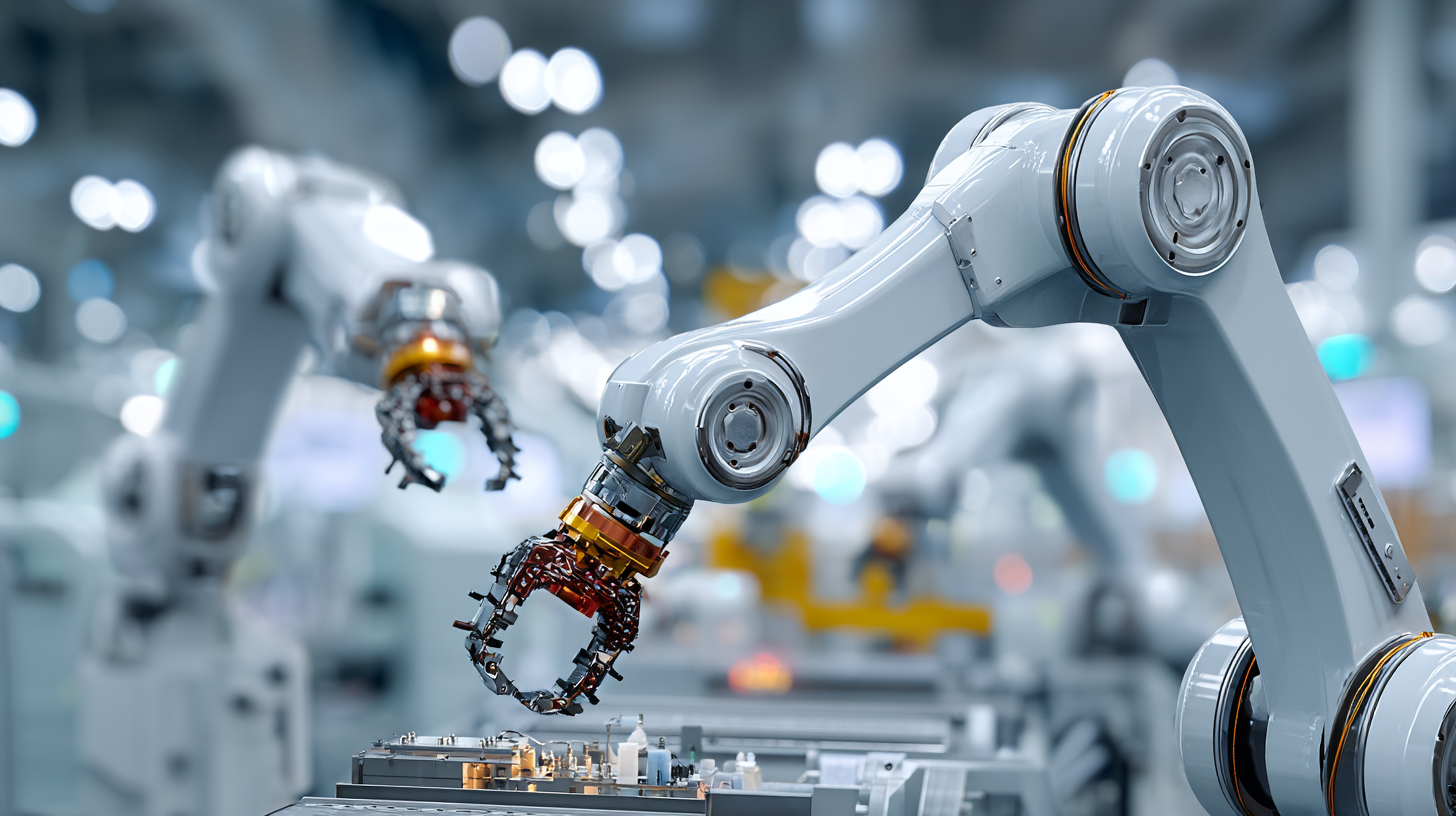

Case Study 1: How Cooperative Robots Enhance Efficiency in Manufacturing

In today's competitive landscape, manufacturing efficiency is a key driver of success, and cooperative robots, or cobots, are transforming how industries operate. A prime example can be seen in an automobile manufacturing plant where cobots work alongside human operators on the assembly line. These robots are designed to handle repetitive tasks, such as lifting heavy parts and tightening bolts, allowing human workers to focus on more complex assembly operations. This synergy not only enhances productivity but also improves workplace safety, as the risk of strain injuries decreases significantly.

Another notable case involves a consumer electronics manufacturer that integrated cobots into its production process. The cobots were programmed to perform quality inspections, using advanced sensors and cameras to detect defects. This collaboration ensured that issues were identified early, substantially reducing the number of faulty products reaching the market. As a result, the company not only enhanced its efficiency but also improved product quality, gaining a competitive edge. The deployment of cooperative robots in manufacturing illustrates how technology can complement human labor, driving innovation and efficiency in real-world applications.

Transforming Industries: Real-World Examples of Cooperative Robots in Action - Case Study 1: How Cooperative Robots Enhance Efficiency in Manufacturing

| Aspect |

Details |

| Industry |

Manufacturing |

| Robot Type |

Cooperative Robots (Cobots) |

| Main Function |

Assisting human workers in assembly tasks |

| Efficiency Improvement |

Increased production rate by 20% |

| Cost Savings |

Reduced labor costs by 15% |

| Worker Safety |

Enhanced worker safety through collaborative operation |

| Implementation Duration |

2 months |

| Employee Satisfaction |

85% satisfaction rate after implementation |

Case Study 2: Transforming Healthcare with Surgical Cooperative Robots

Surgical cooperative robots are revolutionizing the healthcare industry by enhancing precision and reducing recovery times for patients. According to a report by MarketsandMarkets, the surgical robotics market is projected to reach $24.6 billion by 2026, growing at a compound annual growth rate (CAGR) of 12.1%. These advancements not only streamline surgical procedures but also significantly increase the range of motion and control for surgeons, leading to better patient outcomes.

Surgical cooperative robots are revolutionizing the healthcare industry by enhancing precision and reducing recovery times for patients. According to a report by MarketsandMarkets, the surgical robotics market is projected to reach $24.6 billion by 2026, growing at a compound annual growth rate (CAGR) of 12.1%. These advancements not only streamline surgical procedures but also significantly increase the range of motion and control for surgeons, leading to better patient outcomes.

One of the most notable examples of surgical cooperative robots is the da Vinci Surgical System, which has been utilized in over 6 million procedures worldwide. This robotic platform allows for minimally invasive surgeries, significantly reducing hospital stays and recovery times. In fact, studies show that patients who undergo robotic-assisted surgery experience 20% less postoperative pain and a 50% reduction in complications compared to traditional methods.

Tip: When considering the integration of surgical robots in healthcare facilities, it's crucial to ensure proper training for surgeons and support staff to fully leverage the technology's capabilities. Moreover, investing in regular maintenance and upgrades can prolong the life and efficiency of robotic systems, enhancing patient experiences and outcomes. Embracing surgical cooperative robots is not just about adopting new technology; it's about fundamentally transforming patient care.

Exploring the Challenges and Solutions in Implementing Cooperative Robots

The integration of cooperative robots, or cobots, into various industries has revolutionized workflows and productivity. However, this transformation is not without its challenges. One major obstacle is the need for safe human-robot collaboration. Unlike traditional robots that operate in isolation, cobots work alongside human workers, necessitating advanced safety measures and real-time communication systems to prevent accidents and ensure smooth interactions.

Organizations must invest in robust training programs for employees to adapt to this new working environment, ensuring they can effectively collaborate with these intelligent machines.

Another challenge lies in the compatibility of cobots with existing systems. Many companies have legacy equipment that may not easily integrate with modern cobotic solutions. This can lead to increased costs and extended downtimes during the transition phase.

To address this, manufacturers are focusing on designing modular, flexible cobots that can be easily adapted to various settings. Developing user-friendly interfaces and providing comprehensive support during the implementation phase are essential for easing the integration process and maximizing the benefits of cooperative robots in the workforce.

By embracing these solutions, companies can overcome barriers and fully harness the potential of cobots to enhance operational efficiency.

Surgical cooperative robots are revolutionizing the healthcare industry by enhancing precision and reducing recovery times for patients. According to a report by MarketsandMarkets, the surgical robotics market is projected to reach

Surgical cooperative robots are revolutionizing the healthcare industry by enhancing precision and reducing recovery times for patients. According to a report by MarketsandMarkets, the surgical robotics market is projected to reach